Machine Parts of Tin Can Making Equipment

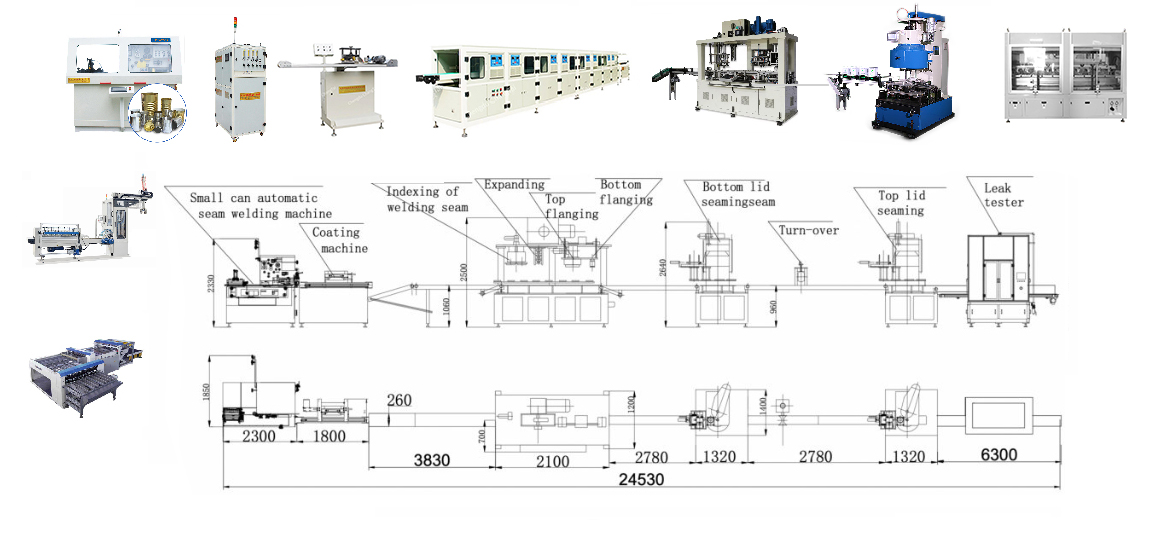

The production of tin cans involves several critical stages, each requiring specific machinery components:

- Slitting Machines: These machines cut large coils of metal into smaller sheets suitable for can production. Precision in cutting is crucial to ensure the uniformity of the can bodies.

- Flanging Machines: After cutting, the can bodies need their edges flanged for sealing. Chengdu Changtai offers flanging machines which are essential for preparing the cans for the sealing process, ensuring they are air-tight.

- Welding Machines: For three-piece cans, welding machines join the body seam. Chengdu Changtai’s welding machines are known for their high speed, yield, and low maintenance rates, with capabilities to work with various metal types like tinplate, chrome, and galvanized plate. Their machines use resistance heating, a method that ensures a robust weld with minimal defects.

- Sealing Machines: Once the body is formed and welded, it must be sealed. Chengdu Changtai supplies automatic canning seamer machines that are pivotal in creating an air-tight seal, which is vital for preserving the contents, be it food, chemicals, or beverages.

- Coating and Drying Equipment: To prevent corrosion, the inside of the can is coated. Chengdu Changtai’s equipment includes options for both spray and roller coating, with subsequent drying systems to cure the coating effectively.

- Inspection and Leak Detection: Quality control is crucial, and Chengdu Changtai integrates machines for testing can integrity, ensuring no leaks or manufacturing defects occur. These machines use techniques like vacuum or pressure testing for thorough inspection.

Chengdu Changtai Intelligent’s Tin Can Making Machines

Chengdu Changtai Intelligent Equipment Co., Ltd., established in 2007, has emerged as a leader in the can-making equipment industry. Their focus on integrating research, development, production, and sales has allowed them to offer:

Automated Production Lines: Their lines are designed for high efficiency, capable of producing different can types from food cans to aerosol cans. They emphasize automation to reduce human error and increase production speed.

Customization and After-Sales Support: Understanding that each client might have unique needs, Changtai provides customization services. Their after-sales support includes installation, commissioning, training, and maintenance, ensuring clients can maximize the utility of their investments.

Innovative Design: Their machines incorporate advanced technology to handle various can shapes and sizes, with features like high-frequency electromagnetic drying for welding seams, which eliminates the need for cold water, thus improving energy efficiency.

Global Reach: Chengdu Changtai’s machines are not just localized; they have a significant international presence, attending exhibitions like Cannex & Fillex Asia Pacific and Metpack in Germany, showcasing their commitment to global standards.

Tin can making industry

The tin can making industry relies on intricate machinery where each part plays a critical role in producing cans that meet stringent quality standards. Chengdu Changtai Intelligent Equipment Co., Ltd. stands out with its comprehensive approach to machinery production, offering solutions that are not only technologically advanced but also tailored to meet the diverse needs of the global market. Their dedication to innovation and customer service makes them a significant player in the evolution of can manufacturing technology.

Contact for tin can making machine:

Website: https://www.ctcanmachine.com

Tel:+86 138 0801 1206

Whatsapp:+86 138 0801 1206

Email:neo@ctcanmachine.com

Post time: Mar-20-2025