Three-Piece Can Making Machine: Revolutionizing the Can Manufacturing Industry

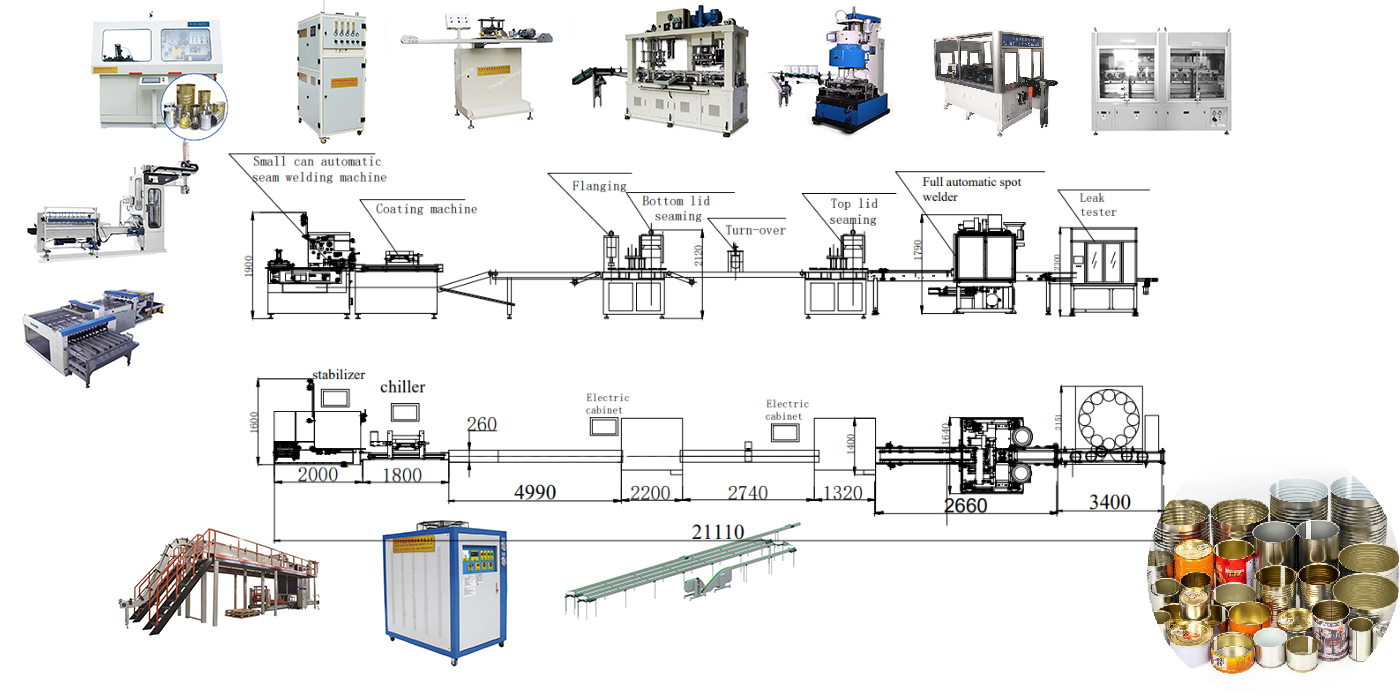

In the modern can making industry, especially for beverage packaging, the demand for efficient and high-quality production lines has never been higher. Among the various solutions, the Three-piece can making machine stands as a key player in the production of durable and reliable metal cans. These machines, including their critical components such as can body welding machines, tin can body forming equipment, and welded seam can body machines, ensure that beverage cans and other types of metal containers meet both industry standards and consumer needs.

Chengdu Changtai, a Chinese national grade manufacturer, is a leader in the can-making equipment industry, providing top-tier machinery that enhances the efficiency of the can production process. Their range of tin can manufacturing equipment includes specialized cylindrical can forming machines, automatic seam welders for cans, and can body resistance welders, all designed to optimize the production of metal cans.

Tin Can Body Production System

The tin can body production system forms the backbone of any high-volume can making operation. At the heart of this system is the can body welding production line, a critical machine that assembles the cylindrical structure of the can. The can body welder machine plays a vital role in welding the edges of tinplate or other metal sheets to form a seamless, high-strength can body. These systems ensure that every can produced is uniform and free from structural flaws, which is crucial for maintaining the quality of the product contained within.

In the welded seam can body machine, the focus is on welding the side seams of the can body, an essential process in the overall production of a sturdy container. With cutting-edge technology such as can body resistance welders, these machines are capable of performing high-speed, precise welding that ensures tight and reliable seams. As a result, cans are less likely to fail under pressure, whether from internal carbonation or external handling.

Metal Can Fabrication Machines and Can Production Automation

The evolution of the metal can fabrication machine has significantly contributed to the automation of the can production process. With machines such as the can production automation machine and steel can fabrication machine, manufacturers can produce large volumes of cans in a shorter amount of time, reducing labor costs and improving overall efficiency. The can body line equipment can seamlessly integrate various steps, from tin can body forming equipment to final welding, offering a fully automated solution for can manufacturers.

Moreover, welding machines for can manufacturing—such as the industrial can welder—offer additional flexibility in the types of cans that can be produced. Whether working with tinplate, steel, or other metals, these welding machines ensure that the cans are built to last, with each seam and weld meticulously constructed to meet international safety and quality standards.

Beverage Can Forming Machines

The beverage can forming machine is another integral piece of equipment in the production of cans, especially for the food and beverage industry. This machine shapes the metal into the standard cylindrical can body that is used for beverages, including soda, beer, and energy drinks. These machines often work in conjunction with metal can end making machines, which create the ends or lids of the cans, ensuring a perfectly sealed product.

Chengdu Changtai’s Role in the Industry

As a prominent player in the industry, Chengdu Changtai offers a range of high-performance solutions tailored to the specific needs of can manufacturers. Their three-piece can making machine and supporting equipment, such as the tin can body forming equipment and can body welder machines, exemplify their commitment to providing efficient, reliable, and precise machines for the metal can manufacturing industry.

With a focus on quality and innovation, Chengdu Changtai continues to lead the way in transforming the can production process, offering solutions that enhance the speed, efficiency, and consistency of the metal can manufacturing process.

The three-piece can making machine and related equipment are critical for modern can manufacturers, ensuring the production of high-quality, durable, and reliable metal cans. Chengdu Changtai, with its advanced technology, continues to provide industry-leading solutions that meet the demands of an ever-evolving market.

Post time: Dec-04-2024