Advancements in Automation and Efficiency

Tin cans have long been a staple in the packaging industry, providing durability, versatility, and protection for a variety of food and non-food products. From their early roots in the 19th century to today's state-of-the-art equipment, the history of tin can making machines has been marked by constant innovation. In this article, we explore the evolution of these machines, their impact on the manufacturing process, and how modern manufacturers, like Changtai Can Manufacture, deliver high-performance, reliable can making equipment to meet growing global demands.

Early Beginnings and Manual Can Production

The origins of tin can manufacturing date back to the early 1800s when the first tin-plated steel cans were introduced. These early cans were produced manually, with workers using simple tools to cut, form, and seal the cans. The process was labor-intensive and inefficient, which limited the scalability of can production. At this point, the machines used for tin can fabrication were rudimentary, and only a limited range of products could be packaged in cans.

The advent of steam-powered machinery during the Industrial Revolution set the stage for significant improvements in production speed and efficiency. As industries grew, so did the demand for faster and more reliable can-making machines. This led to the development of automated systems that could handle tasks such as cutting, forming, and welding can bodies.

Advancements in Can Manufacturing Technology

By the early 20th century, the first automated food tin cans machines began to emerge. These machines integrated multiple steps of the manufacturing process, including the can body forming, can body production, and can body welding. Innovations such as the can body welder machine allowed for more precise and efficient production, reducing the need for manual labor and improving the quality of the final product.

Around this time, pails and drum making machines also began to gain popularity. These machines were designed specifically for larger containers, such as metal pails and drums, which were commonly used in industries like chemicals, paints, and food storage. The machines used for producing these containers shared some similarities with traditional tin can manufacturing machines but were adapted to handle larger and bulkier forms.

As demand for canned goods grew, especially with the rise of packaged food products, there was an increasing need for more specialized can-making machines. One of the most notable advancements was the development of the Milk Powder Tin Can Making Machine. This machine was specifically designed to handle the unique requirements of packaging milk powder, which necessitated airtight seals to preserve freshness and prevent contamination.

Modernization and Efficiency

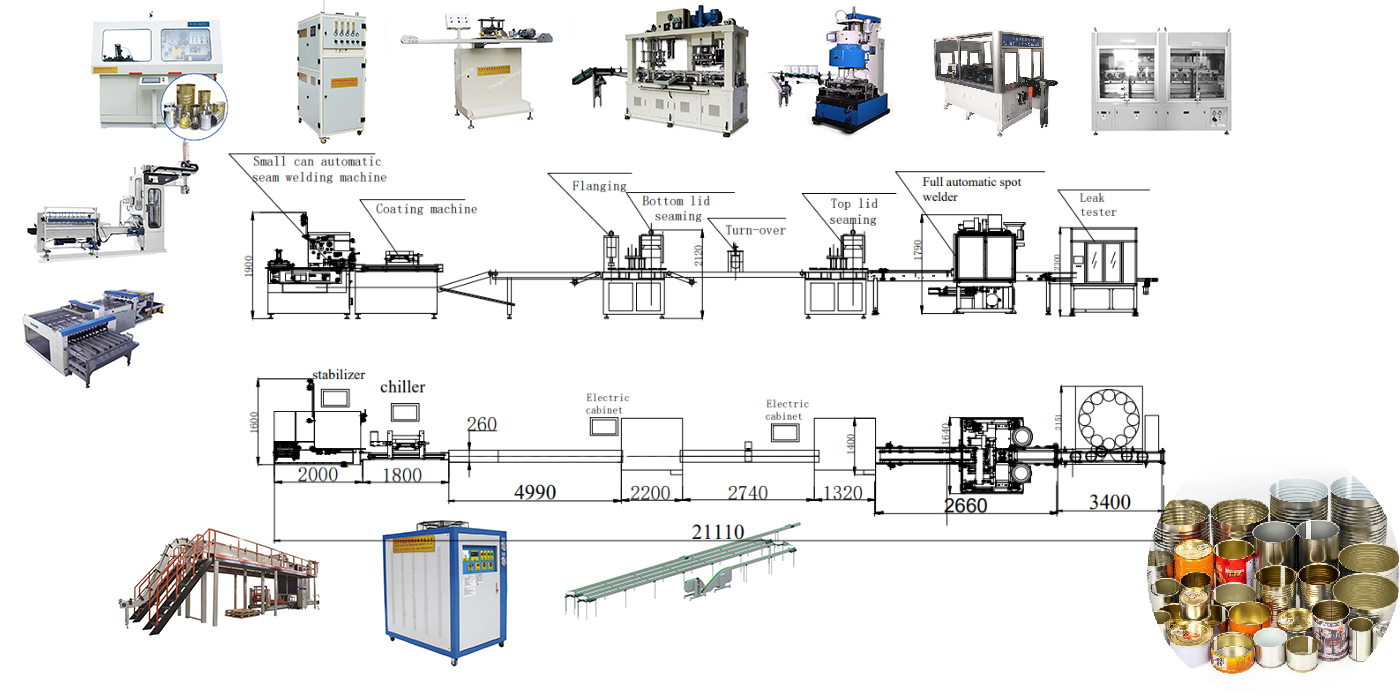

The second half of the 20th century saw rapid advancements in can manufacturing technology, with the introduction of high-speed automated lines capable of producing large volumes of cans in a fraction of the time it previously took. The line for cans now includes machines that can perform multiple operations simultaneously, such as can body forming, welding, and seaming. The tin can seamer is one such machine that plays a crucial role in this process by sealing the top of the can after it has been filled, ensuring a secure, tamper-proof closure.

The Drum Welder, which specializes in welding metal drums, also emerged during this period. These machines could automatically form and weld the body of the drum, significantly reducing production time and minimizing the risk of defects. Similar technological advancements were made in the field of food can manufacturing, with more automated machines dedicated to producing cans for various food products, from vegetables and fruits to seafood and ready-to-eat meals.

One of the most significant technological advancements in modern can-making equipment has been the development of food can welding machines. These machines are designed to create precise and reliable welds, ensuring that cans are fully sealed and free from defects. The ability to manufacture high-quality food cans in large quantities has revolutionized the food industry, enabling companies to meet increasing demand while maintaining strict quality control standards.

The Role of Changtai Can Manufacture in Modern Can Making

As the demand for efficient, high-performance can making machinery continues to rise, manufacturers like Changtai Can Manufacture have become key players in the industry. With decades of experience in designing and producing reliable can making equipment, Changtai is renowned for its ability to deliver cutting-edge solutions for can manufacturers worldwide.

Changtai's product lineup includes everything from food tin cans machines and steel can fabrication machines to specialized tin can canners and food can body makers. Their machines are designed to handle the full spectrum of can production, including can body forming, welding, and seaming, making them an indispensable part of modern canning operations.

Changtai’s commitment to innovation and quality has earned them a reputation as one of the leading suppliers of high-performance can making equipment. The company's machines are known for their reliability, precision, and durability, ensuring that customers can achieve high production rates without sacrificing quality.

With the industry's growing focus on automation and efficiency, Changtai's machines are designed to operate with minimal human intervention, reducing labor costs and enhancing overall productivity. Furthermore, Changtai's equipment is built to accommodate a wide range of can types and sizes, from small food cans to large drums and pails.

The history of tin can making machines has been a story of constant innovation, driven by the need for faster, more efficient production methods. From manual processes to fully automated systems, the development of can manufacturing technology has transformed the packaging industry. Today, machines such as the can body welder machine, food tin cans machines, and Drum Welders play a crucial role in producing cans for everything from food products to chemicals.

As the global demand for canned goods continues to rise, companies like Changtai Can Manufacture are at the forefront of delivering advanced, reliable, and high-performance can making equipment. Their comprehensive range of machines ensures that manufacturers can meet the increasing demands of the industry while maintaining the highest standards of quality.

Click here to learn more about how Changtai Can Manufacture can deliver cutting-edge solutions for your can making needs.

Post time: Dec-03-2024