what parts are included in semi-atuomatic can making machinery?

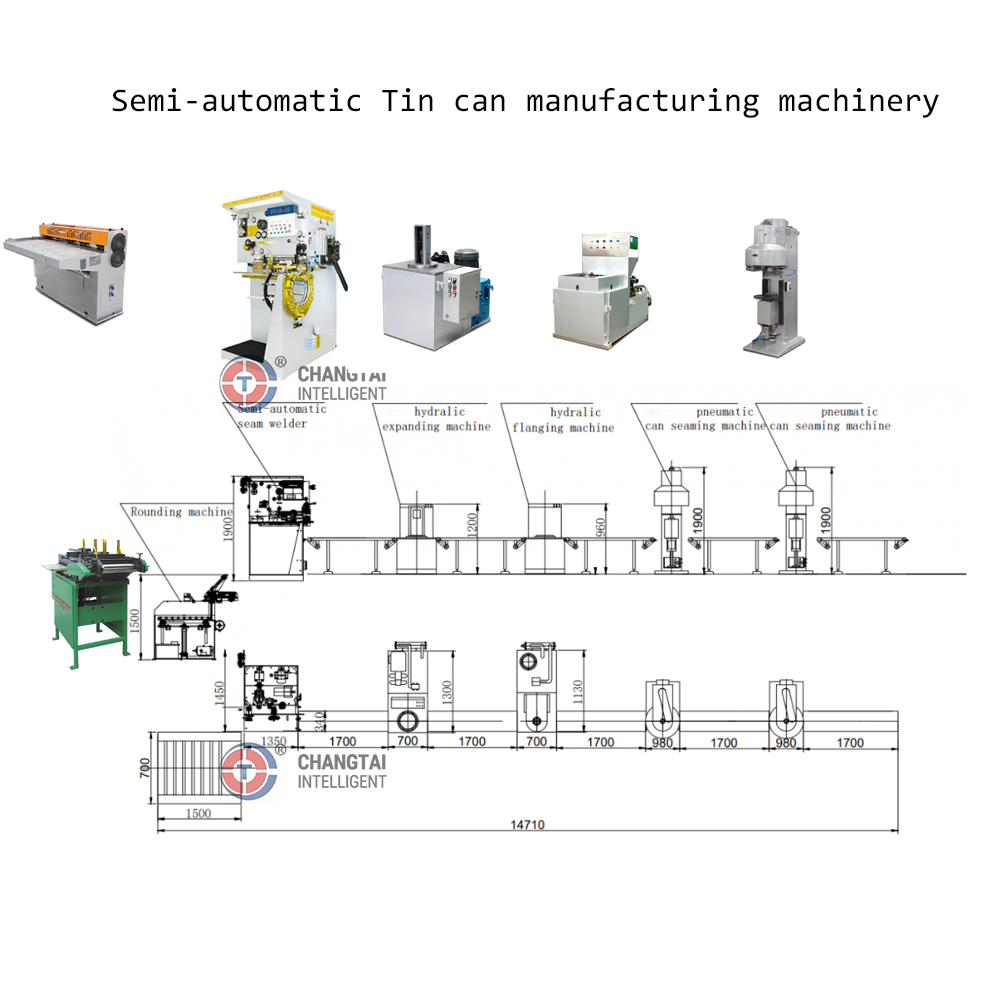

Semi-automatic can making machinery typically includes several key components necessary for the production of cans. Here are some common parts you might find in such machinery:

A. Feeding System: This part is responsible for feeding the raw material, usually metal sheets or coils, into the machine for processing.

B. Sheet Cutting Mechanism: If the raw material is supplied in large sheets or coils, a cutting mechanism is employed to cut the sheets into the required size for can production.

C. Forming Station: This is where the metal sheets are formed into the cylindrical shape of the can body. It may involve processes such as drawing and ironing.

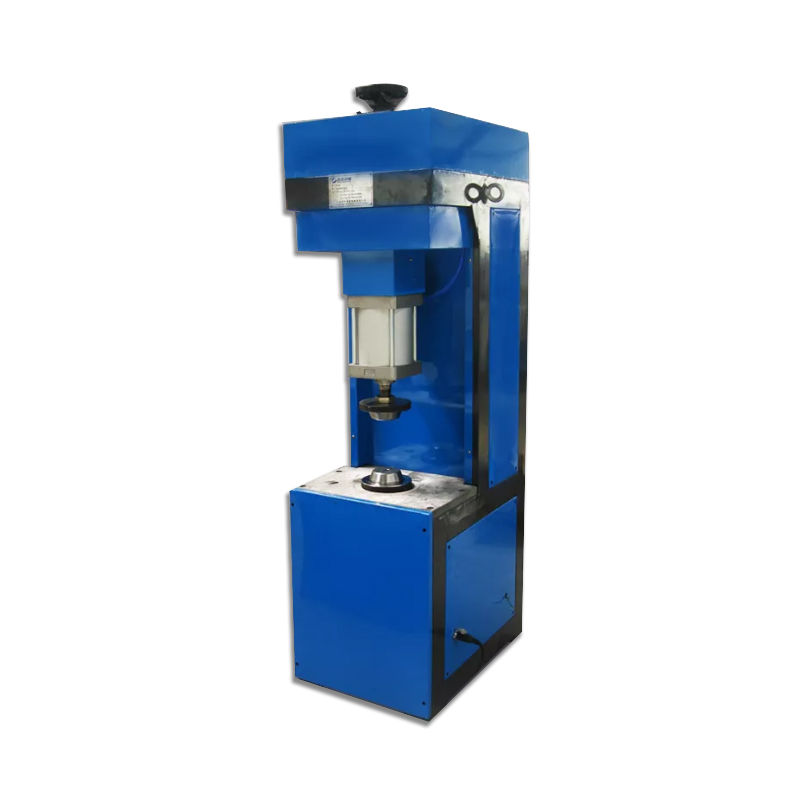

D. Seaming Station: Once the can bodies are formed, they need to be seamed to create airtight seals. This station typically includes mechanisms for joining the can body with the top and bottom ends.

E. Lid Feeder: For cans that require separate lids, a lid feeder mechanism may be included to supply lids to the seaming station.

F. Control Panel: A control panel is essential for operating and monitoring the machinery. It allows operators to set parameters, monitor production progress, and troubleshoot issues.

G. Safety Features: Semi-automatic machinery should include safety features such as emergency stop buttons, safety guards, and sensors to ensure the safety of operators.

H. Optional Components: Depending on the specific design and functionality, semi-automatic can making machinery may include additional components such as lubrication systems, quality control mechanisms, and conveyor systems for moving cans between stations.

These are the basic parts you would expect to find in semi-automatic can making machinery, but the exact configuration can vary depending on factors such as the size of the cans being produced and the specific manufacturing process used.

Advantages of Semi-Automatic Can Making Machines

In the dynamic of modern can making industry, efficiency and precision are paramount. Nowhere is this more evident than in the production of cans, which are ubiquitous in industries ranging from food and beverage to pharmaceuticals. The advent of semi-automatic can making machines has revolutionized this process, offering a blend of automation and human oversight that maximizes output while maintaining quality. Let's delve into the components, advantages, and a prime example of these innovative machines with Chengdu Changtai Intelligent leading the charge.

Semi-automatic can making machines comprise several essential components, each playing a crucial role in the seamless production process. At their core, these machines typically feature a feeding system that transports raw materials, such as metal sheets, to the subsequent stages. Following this, a shaping mechanism forms the sheets into cylindrical shapes, which are then welded or sealed to create the can's body. Additional components, such as labeling and packaging modules, may be integrated to facilitate a comprehensive production workflow.

One of the primary advantages of semi-automatic can making machines lies in their ability to strike a balance between automation and manual intervention. While certain tasks are handled autonomously by the machine, human operators oversee the process, ensuring that any irregularities are promptly addressed. This human-machine collaboration not only enhances the overall efficiency of production but also allows for greater flexibility in adapting to diverse production requirements.

Furthermore, semi-automatic machines offer considerable versatility, accommodating various can sizes, shapes, and materials with minimal reconfiguration. This adaptability is particularly advantageous in industries where product specifications frequently change, enabling manufacturers to swiftly adjust their production lines to meet evolving demands. Additionally, the modular design of these machines facilitates easy maintenance and upgrades, further enhancing their longevity and operational efficiency.

Now, let's spotlight Chengdu Changtai Intelligent as an exemplar in providing state-of-the-art semi-automatic can making equipment. With a steadfast commitment to innovation and quality, Chengdu Changtai Intelligent has established itself as a leading player in the can industry. Their range of machines embodies cutting-edge technology, integrating advanced features such as precision shaping mechanisms, intelligent control systems, and seamless material handling capabilities.

Chengdu Changtai Intelligent's semi-automatic can making machines are engineered to deliver unparalleled performance and reliability. Equipped with high-speed processing capabilities, these machines ensure rapid production cycles without compromising on precision or quality. Moreover, their user-friendly interfaces and intuitive controls empower operators to optimize production parameters effortlessly, thereby maximizing efficiency and minimizing downtime.

In addition to technological prowess, Chengdu Changtai Intelligent places a strong emphasis on customer satisfaction and support. Their dedicated team of professionals offers comprehensive assistance, from initial installation and training to ongoing maintenance and technical support. By forging collaborative partnerships with clients, Chengdu Changtai Intelligent strives to exceed expectations and drive continuous innovation in the can manufacturing landscape.

Semi-automatic can making machines represent a transformative advancement in modern manufacturing, offering unparalleled efficiency, flexibility, and quality. With industry leaders like Chengdu Changtai Intelligent at the forefront, the future of can production is characterized by innovation, precision, and excellence. As demand for canned goods continues to rise across various sectors, these machines serve as indispensable tools in meeting evolving consumer needs and driving sustained growth in the global marketplace.

Related Video of Tin Can Welding Machine

Chengdu Changtai Intelligent Equipment Co., Ltd.- A automatic can equipment Manufacturer and Exporter, provides all the solutions for Tin can making. To know the latest news of metal packing industry, Find new tin can making production line, and get the prices about Machine For Can Making,Choose Quality Can Making Machine At Changtai.

Contact us for details of machinery:

Email:tiger@ctcanmachine.com

Post time: Oct-06-2024