For canning machinery, regular maintenance and servicing are essential. Not only does this help extend the equipment’s operational lifespan, but it also ensures safer operation. So, when is the best time to maintain and service canning machinery? Let’s take a closer look.

Step 1: Regular Inspection of Key Parts in Canning Machinery

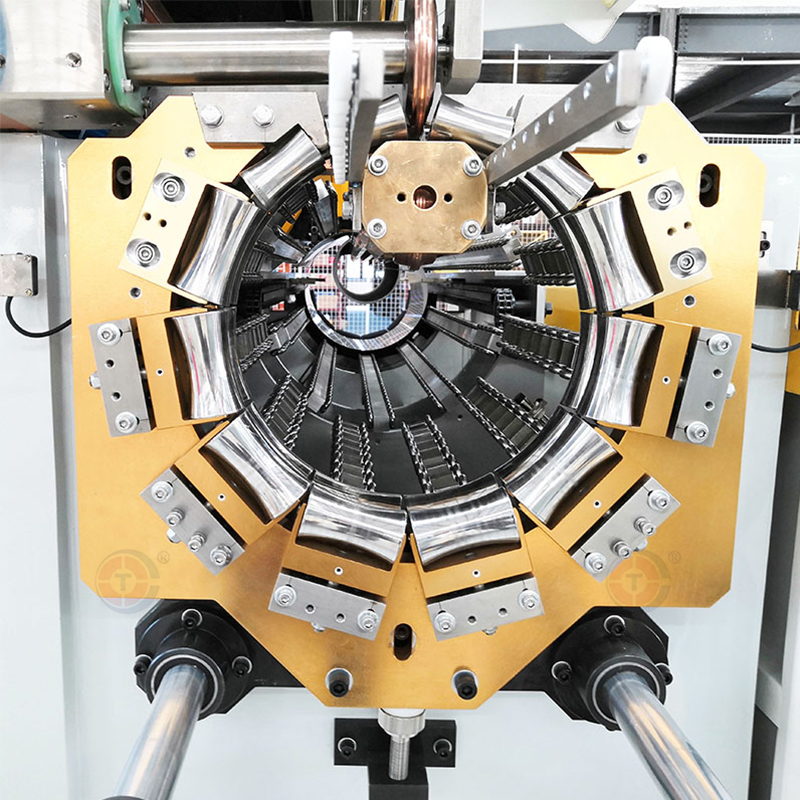

When installing canning machinery, it’s important to inspect key components such as bearings and bolts, and to keep detailed records of these inspections. This provides a reference for future maintenance.

Step 2: Regular Lubrication and Major Overhaul Requirements

Adding lubrication at regular intervals allows the equipment to operate more smoothly and reduces the likelihood of malfunctions.

If the canning machinery shows significant wear or a noticeable drop in performance, a thorough, comprehensive repair should be carried out. This is the time to conduct a major overhaul and inspection of the equipment.

These are Changtai Intelligent’s recommendations for clients, aimed at providing useful guidance. Regular maintenance can bring greater benefits to all clients using canning machinery.

Post time: May-12-2024