Food Cans (3-Piece Tinplate Can) Buying Guide

A 3-piece tinplate can is a common type of food can made from tinplate and consists of three distinct parts: the body, the top lid, and the bottom lid. These cans are widely used for preserving a variety of food items like fruits, vegetables, meat, and soups. Here's a guide to help you make informed decisions when purchasing them:

Buying Guide

1. Structure and Design

- Three-Piece Construction: These cans are called "three-piece" because they are composed of a cylindrical body with two end pieces (top and bottom). The body is typically formed from a flat piece of tinplate that is rolled into a cylinder and welded or seamed along the side.

- Double Seaming: Both the top and bottom lids are attached to the body using a process called double seaming, which creates a hermetic seal to prevent contamination and leakage.

2. Material Quality

- Tinplate Material: Tinplate is steel coated with a thin layer of tin to protect against corrosion. It offers excellent strength and durability, making it ideal for food preservation. When buying 3-piece tinplate cans, ensure that the tin coating is of good quality to prevent rusting and spoilage.

- Thickness: The thickness of the tinplate can affect the can's durability and resistance to dents. For products that require long-term storage or shipping, thicker tinplate may be a better choice.

3. Coatings and Linings

- Internal Coatings: Inside the can, coatings like enamel or lacquer are applied to prevent the food from reacting with the metal. Acidic foods, like tomatoes and citrus fruits, require specific linings to prevent corrosion and ensure safety.

- BPA-Free Options: Opt for BPA-free linings to avoid potential health risks associated with Bisphenol A, a chemical sometimes used in can linings. Many manufacturers now offer BPA-free alternatives that are just as effective at preserving food.

4. Sizes and Capacities

- Standard Sizes: 3-piece tinplate cans are available in various sizes, typically measured in ounces or milliliters. Common sizes include 8 oz, 16 oz, 32 oz, and larger. Choose the size based on your storage needs and the type of food you intend to preserve.

- Custom Sizes: Some suppliers offer custom sizes for specific food products or packaging requirements. If you need a particular size or shape, inquire about custom orders.

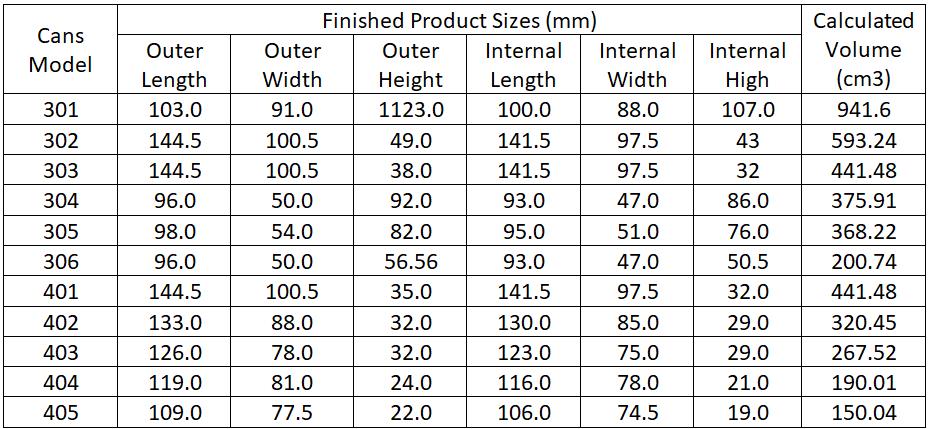

Rectangular cans sizes

5. Seaming Technology

- Welded vs. Soldered Seams: Welded seams are more common in modern manufacturing as they provide a stronger, leak-proof seal compared to soldered seams, which use a filler metal. Ensure that the cans you purchase use high-quality welding technology for a better seal.

- Leak Testing: Check if the manufacturer performs leak testing on the cans. Proper testing ensures that the cans will maintain their integrity during storage and transportation.

6. Labeling and Printing

- Plain vs. Printed Cans: You can purchase plain cans for your labeling, or opt for pre-printed cans with custom branding. If you're buying in bulk for commercial use, consider printing labels directly onto the can for a professional appearance.

- Label Adhesion: If you plan to add adhesive labels, ensure the surface of the can is suitable for labels to stick securely, even in varying temperature and humidity conditions.

7. Environmental Considerations

- Recyclability: Tinplate cans are 100% recyclable, making them an eco-friendly option. Steel is one of the most recycled materials globally, so using these cans helps reduce environmental impact.

- Sustainable Sourcing: Look for suppliers who focus on sustainable manufacturing practices, such as reducing energy consumption and minimizing waste in production.

8. Safety and Compliance

- Food Safety Standards: Ensure that the cans meet relevant food safety standards, such as FDA regulations in the U.S. or European food packaging standards. Compliance with these standards ensures that the cans are safe for direct food contact.

- Corrosion Resistance: Make sure the cans are tested for corrosion resistance, especially if you're packaging acidic or high-salt content foods.

9. Cost and Availability

- Bulk Purchasing: 3-piece tinplate cans are often more cost-effective when purchased in bulk. If you're a manufacturer or retailer, explore wholesale options for better pricing.

- Supplier Reputation: Work with reputable suppliers who have a track record of delivering high-quality cans. Read reviews or ask for samples before placing large orders.

10. Usage and Storage

- Long-Term Storage: 3-piece tinplate cans are excellent for long-term food storage due to their durability and ability to protect contents from light, air, and moisture.

- Temperature Resistance: Tinplate cans can withstand both high temperatures (during sterilization processes like canning) and cold temperatures (during storage), making them versatile for various food preservation methods.

By considering these factors, you can choose the best 3-piece tinplate cans for your food preservation needs, whether for home use or commercial production.

China leading provider of 3 piece Tin Can Making Machine and Aerosol Can Making Machine, Changtai Intelligent Equipment Co., Ltd. is an experienced Can Making Machine factory.Including parting, shaping, necking, flanging, beading and seaming,Our can making systems feature high-level modularity and process capability and are suitable for a wide range of applications, With fast, simple retooling, they combine extremely high productivity with top product quality, while offering high safety levels and effective protection for operators.

Post time: Aug-17-2024