Introduction

In the metal packaging industry, the choice between three-piece and two-piece can making machines is a critical decision that can significantly impact manufacturing costs, production efficiency, and end-product characteristics. This article aims to analyze the differences between these two types of machines, including their machine requirements, material costs, and end-product characteristics. By understanding these differences, readers can make informed decisions about when a three-piece machine is the better choice.

Manufacturing Differences

Machine Requirements

Three-Piece Can Making Machines

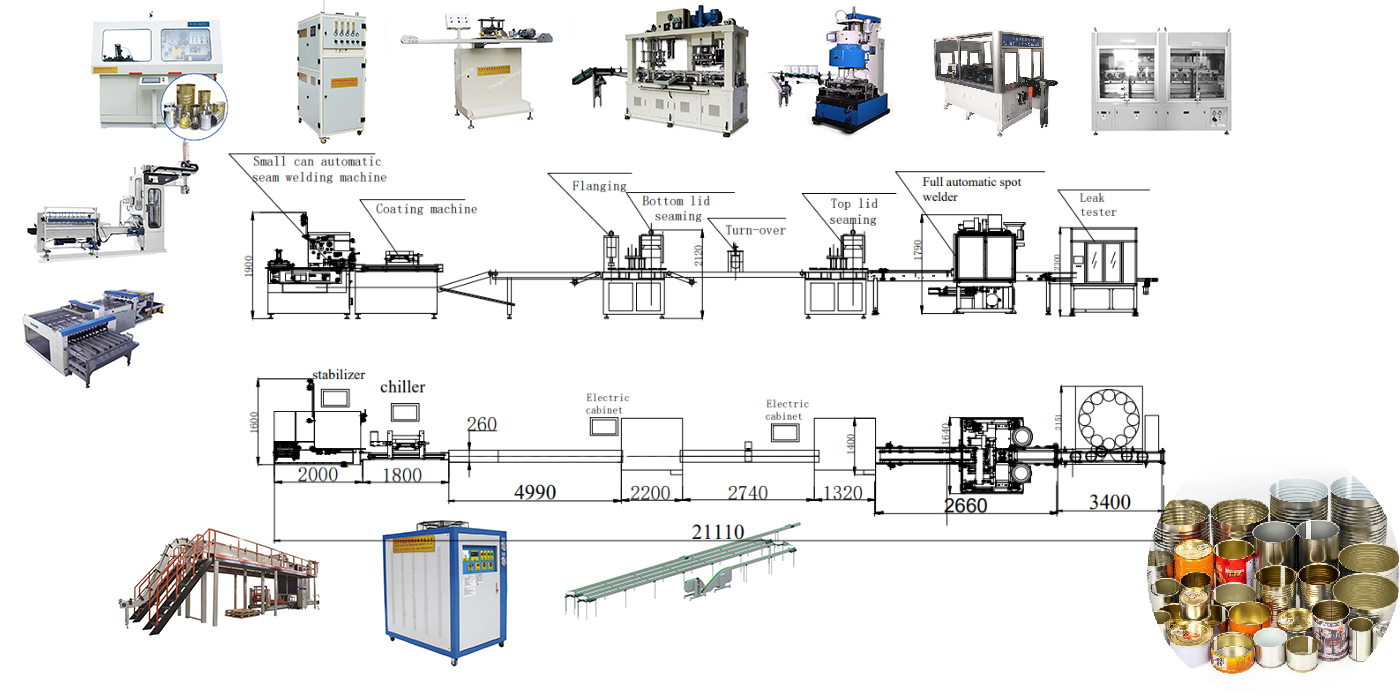

Three-piece can making machines involve three main components: the body, the end (lid), and the seam. These machines typically require more complex machinery and automation to assemble the components accurately. The process includes forming the can body, applying the end, and seaming the two together.

Two-Piece Can Making Machines

In contrast, two-piece can making machines produce cans from a single piece of material, with the end integrated into the body. This design simplifies the manufacturing process and reduces the need for complex machinery. However, it may limit the versatility in terms of can sizes and shapes.

Material Use

Three-Piece Cans

Three-piece cans offer greater flexibility in terms of material use. They can be made from a variety of metals, including aluminum, steel, and tinplate, depending on the specific needs of the end-product. The separate body and end components also allow for more customization in terms of thickness and coating.

Two-Piece Cans

Two-piece cans are typically made from a single type of material, which can limit customization options. However, advancements in material science have led to the development of high-performance materials that can meet a wide range of packaging requirements.

Cost Comparison

Initial Investment

Three-piece can making machines often require a higher initial investment due to their complexity and automation. However, this investment can be justified by the increased versatility and efficiency in production.

Two-piece can making machines, on the other hand, typically have a lower initial investment. They are simpler in design and require less automation, making them more cost-effective for smaller-scale production.

Operating Costs

Operating costs for three-piece can making machines can be higher due to the need for more maintenance and repair. However, the increased efficiency and productivity can offset these costs over time.

Two-piece can making machines generally have lower operating costs due to their simplicity and reliability. They require less maintenance and can operate with fewer personnel.

End-Product Characteristics

Versatility

Three-piece cans offer greater versatility in terms of sizes, shapes, and materials. This makes them ideal for a wide range of applications, including canned food, dairy products, chemicals, and more.

Two-piece cans are limited in terms of versatility. They are typically used for standard sizes and shapes, which may not meet the specific needs of some applications.

Durability

Both three-piece and two-piece cans offer excellent durability and protection for the contents. However, the seam of a three-piece can may be more prone to leaks if not properly sealed. Conversely, two-piece cans have a seamless design that eliminates this risk.

When to Choose a Three-Piece Machine

Based on the analysis above, a three-piece machine is often the better choice when:

- Versatility is a priority: Three-piece cans offer greater customization in terms of sizes, shapes, and materials.

- High production volumes are required: The increased efficiency and productivity of three-piece machines can offset higher operating costs.

- End-product quality is critical: Three-piece cans can provide a higher level of protection and sealing integrity for sensitive contents.

Changtai Intelligent Equipment Co.: Your Solution for Can Making Equipment

For food or chemical production companies looking for industrial metal can-making equipment, Changtai Intelligent Equipment Co. provides a wide range of solutions. Our equipment is widely used for canned food, dairy products packaging, pressure vessels, chemical paints, and the electric power industry. With our expertise in can making machinery, we can help you make informed decisions about the best equipment for your needs.

For any inquiries about can making equipment and metal packing solutions, please contact us at:

- Email: NEO@ctcanmachine.com

- Website: https://www.ctcanmachine.com/

- TEL & Whatsapp: +86 138 0801 1206

The choice between three-piece and two-piece can making machines depends on specific needs in terms of versatility, cost, and end-product characteristics. By understanding these differences, companies can make informed decisions that optimize their production processes and meet the needs of their customers.

Post time: Apr-18-2025