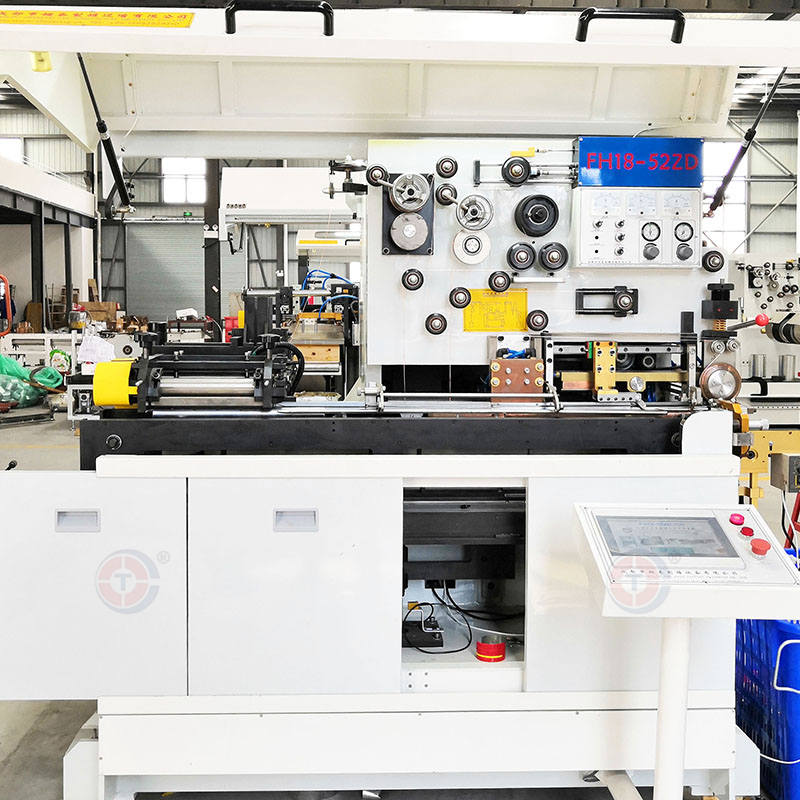

Can welding machine, also called as pail welder, can welder or welding bodymaker,The canbody welder is at the heart of any three-piece can production line. As the Canbody welder take resistance welding solution to weld side seam, it is also named as side seam welder or side seam welding machine.

The seam welding machine for can-making equipment offers the following key benefits:

1. High production efficiency: The seam welding machine automates the welding process, significantly improving production efficiency, especially in high-volume production settings. It can shorten lead times and reduce costs.

2. High welding quality: The machine uses mechanical drive and automatic control, ensuring constant speed and stable welding force. This results in welds of consistent high quality and reduces welding defects caused by human error.

3. Easy control of process parameters: The welding current, wire feed speed, and head movement speed can be precisely set and adjusted. This makes it easier to monitor and optimize the welding process.

4. Labor savings: By automating the welding process, the seam welding machine greatly reduces the need for manual labor, particularly in repetitive and simple welding tasks.

5. Reduced labor intensity: The machine automates wire supply and head guidance, allowing operators to monitor and adjust the machine during use without staying in welding positions for long periods, thus reducing physical strain.

6.Strong adaptability to environmental conditions: The seam welding machine can precisely control and adjust parameters such as welding current and displacement speed. It can accommodate a wider range of thin plate thicknesses and materials, with less reliance on environmental conditions compared to manual welding.

7. Low operating cost: The machine's automation and standardization of the welding process not only allow precise control over parameters but also enable the reuse of standardized materials like welding wire and protective gas, resulting in lower operating costs.

In summary, the seam welding machine achieves automation and standardization of the welding process, offering high production efficiency, superior welding quality, easy control of process parameters, labor savings, reduced labor intensity, strong environmental

7. Low operating cost: The machine's automation and standardization of the welding process not only allow precise control over parameters but also enable the reuse of standardized materials like welding wire and protective gas, resulting in lower operating costs.

In summary, the seam welding machine achieves automation and standardization of the welding process, offering high production efficiency, superior welding quality, easy control of process parameters, labor savings, reduced labor intensity, strong environmental

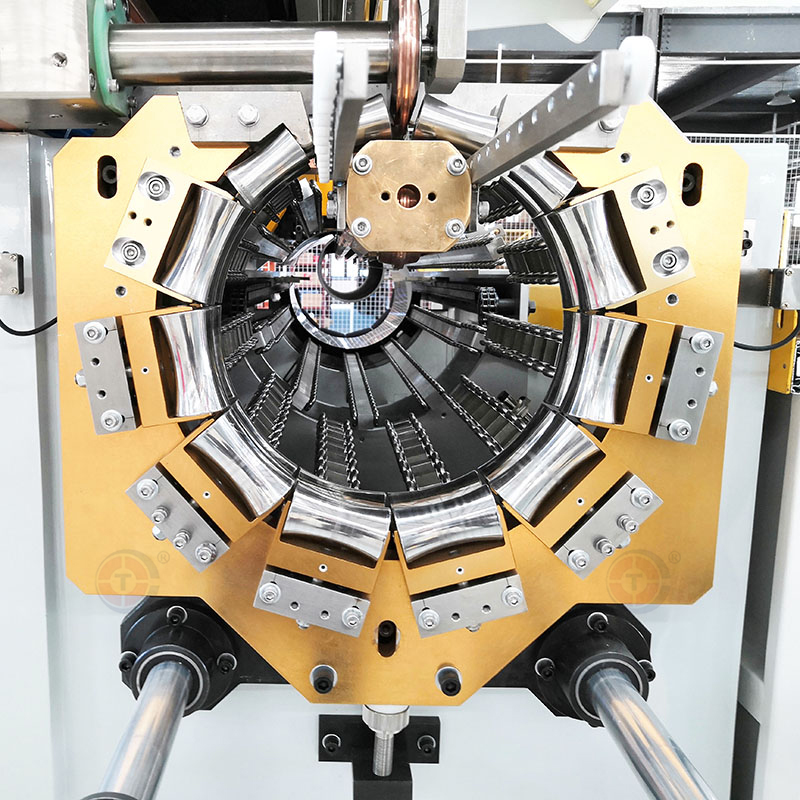

CHANGTAI Intelligent's Can reformer machine and can body shape forming machine are suitable for a wide range of applications, including parting, shaping, necking, flanging, beading and seaming. With fast, simple retooling, they combine extremely high productivity with top product quality, while offering high safety levels and effective protection for operators.

Post time: Nov-28-2024