Automatic double circular knife cutting machine

Automatic double circular knife cutting machine

About duplex slitter

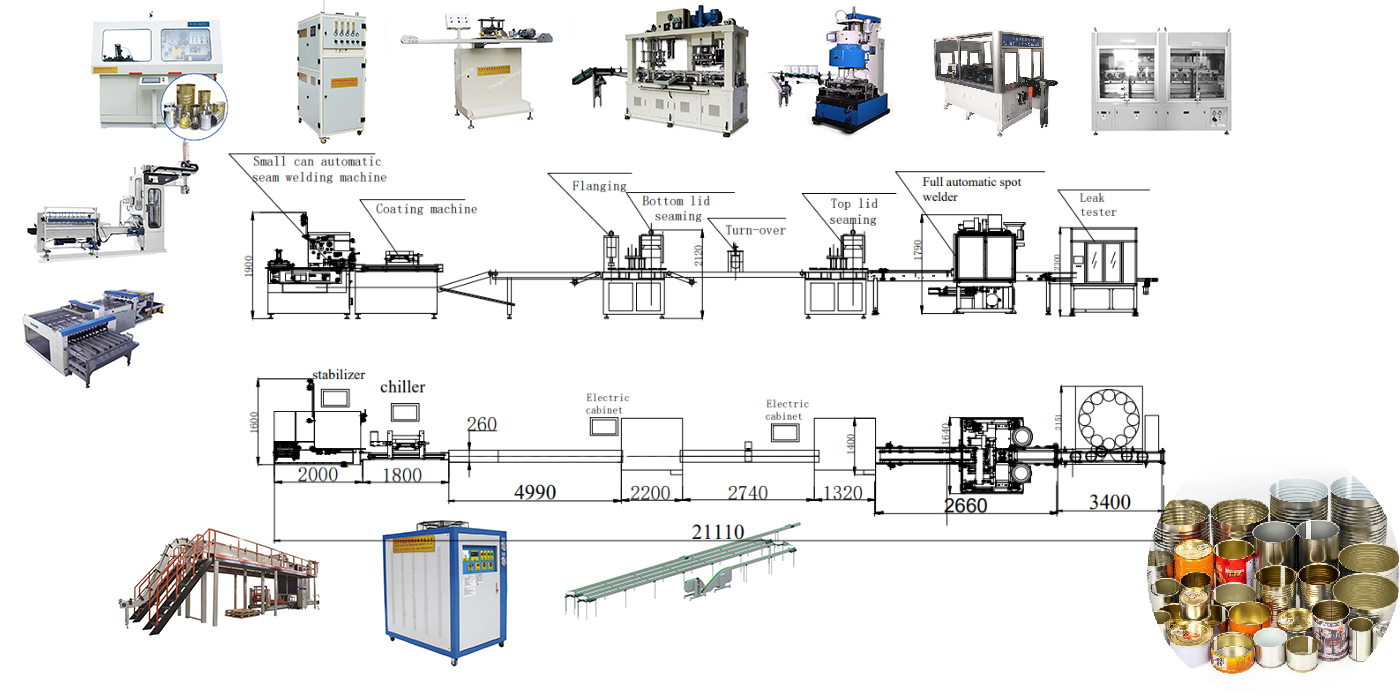

The duplex slitter is one of the most important pieces of equipment in a 3-piece can production line. The slitting machine is used to cut the tinplate into can body blanks in the correct size. Our duplex slitter is high quality and an optimal solution for your metal packaging factory.

Specifically designed for canned food factories and empty can manufacturing plants. It is also suitable for slitting sheet metal into similar sizes for other industries, and can meet the demanding requirements of a high-speed resistance welding machine.

The slitter consists of feeder, shear, electrical control box, vacuum pump, loader and sharpener. The multifunctional slitter is versatility which it can feed automatically, vertical, horizontal cutting automatically, duplex detection and electromagnetism counting.

In short,an automatic duplex slitter works in the procee as follows:

1. Automatic Sheet Feed-in

2. Vertical Slitting,Conveving and positioning, Horizontal slitting

3. Collecting and stacking

They are extremely robust, facilitate simple, swift adjustment to different blank formats and ensure exceptionally high precision.When it comes to versatility, precision, reliability and production speed, our slitters are so suitable for tin canbody producing.

Technical Parameters

| Sheet Thickness |

0.12-0.4mm |

| Sheet length and width size range |

600-1200mm |

| Number of first cut strips |

4 |

| Number of second cuts |

4 |

| First cut width |

160mm-500mm |

| Second cut width |

75mm-1000mm |

| size error |

土 0.02mm |

| Diagonal error |

土 0.05mm |

| glitch |

≤0.015mm |

| Stable production speed |

30 sheets/min |

| power |

About 12Kw |

| Acceptance is based on Baosteel's first-grade iron or equivalent material standards. | |

| Power supply | AC three-phase five-wire (with working grounding and protective grounding) |

| Voltage | 380V |

| Single-phase voltage | 220V±10% |

| Frequency range | 49~50.5Hz |

| Temperature | below 40°C |

| Humidity | below 80% |

More info. of single slitter

The tinplate sheet slitter is the first station of the can making line.

It is used to cut the tinplate sheet or stainless steel sheet as can body blanks of required size or strips for can ends. The duplex slitter or single slitter are versatile, precise and robust.

For the single slitting machine, it is suitable for strip dividing and trimming, and for the duplex slitting machine, it is horizontal cutting with vertical cutting. When the tinplate shearing machine is running, the upper cutter and lower cutter are rolling on the both side of printed and lacquered metal sheets, the quantity of slitting cutters is based on the number of strips and blank formats. The distance between each cutter is easy and swift to adjust, so the type of tinplate cutting machine is also named as gang slitter or gang slitting machine. The carbide cutter is available for the canmaker.

Before the duplex slitting machine or single slitting machine, the automatic sheet feeder is equipped to suck and convey tinplate by sucking disc with pneumatic system and double sheet detection device. After shearing, the collector and stacker can automatically output, and the transfer between slitter and canbody welder is also available.

Higher speed and thinner material needs higher accuracy and brilliant surfaces. The sheets are constantly guided. Conveyors ensure smooth and safe sheet, stripe and blank transport. The single slitter can be completed with a second cutting operation; therefore an investment in a single slitter is an absolutely worthwhile investment if the canbody production output is planned to be increased. Easy to maintain and to operate. For cutting strips or just to trim the sheets. Available for tinplate or for aluminum sheets.