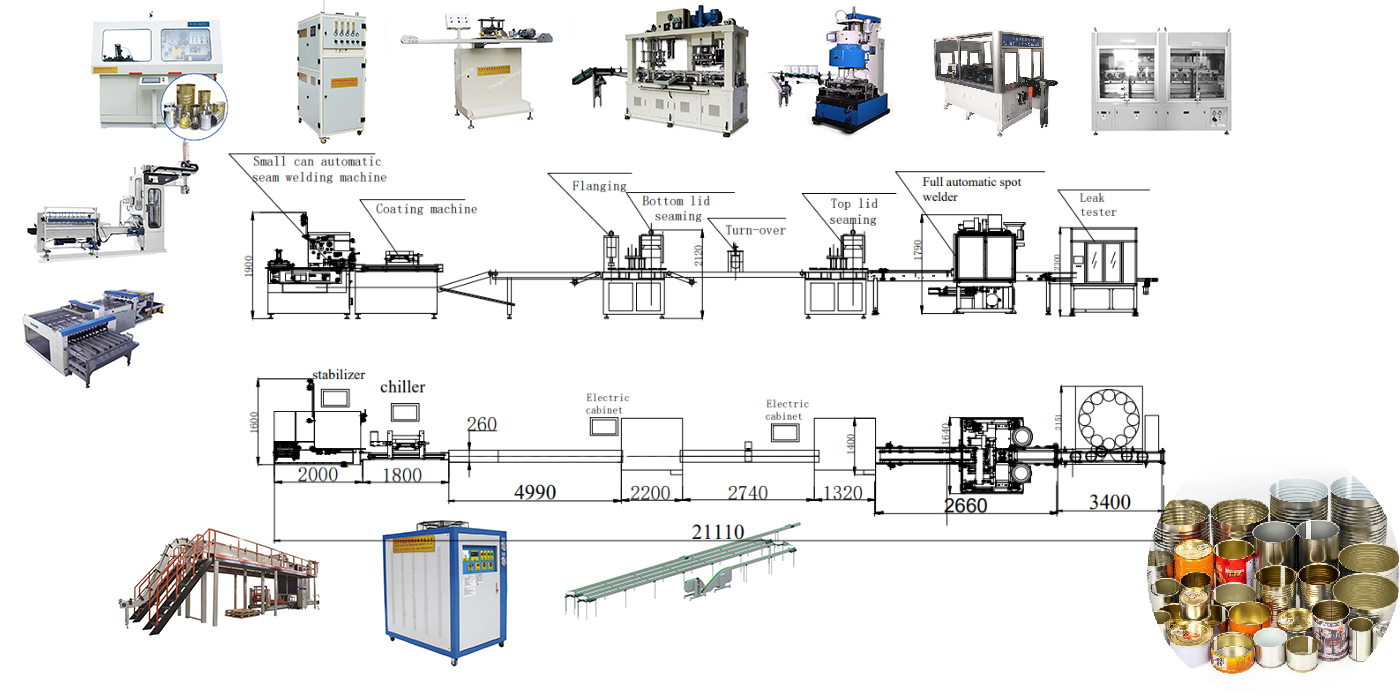

5L-25L Food Cans Oil Cans Round Cans Square Cans Tin Can Seam Welding Machine

5L-25L Food Cans Oil Cans Round Cans Square Cans Tin Can Seam Welding Machine

Technical Parameters

| Model | FH18-65ZD |

| Production Capacity | 40-120cans/min |

| Can Diameter Range | 65-180mm |

| Can Height Range | 60-280mm |

| Material | Tinplate/steel-based/chrome plate |

| Tinplate Thickness Range | 0.2-0.35mm |

| Applicable material Thickness | 1.38mm 1.5mm |

| Cooling Water | Temperature :<=20℃ Pressure:0.4-0.5MpaDischarge:10L/min |

| Power Supply | 380V±5% 50Hz |

| Total Power | 40KVA |

| Machine Measurements | 1750*1100*1800 |

| Weight | 1800kg |

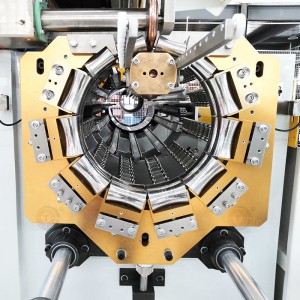

The copper wire cutting knife of the machine is made of alloy material, which has a long service life. The touch screen operation interface is simple and clear at a glance.

The machine is equipped with various protection measures, and when there is a fault, it will be automatically displayed on the touch screen and prompted to deal with it. When checking machine movement, programmable logic controller (PLC) input and output points can be read directly on the touch screen.

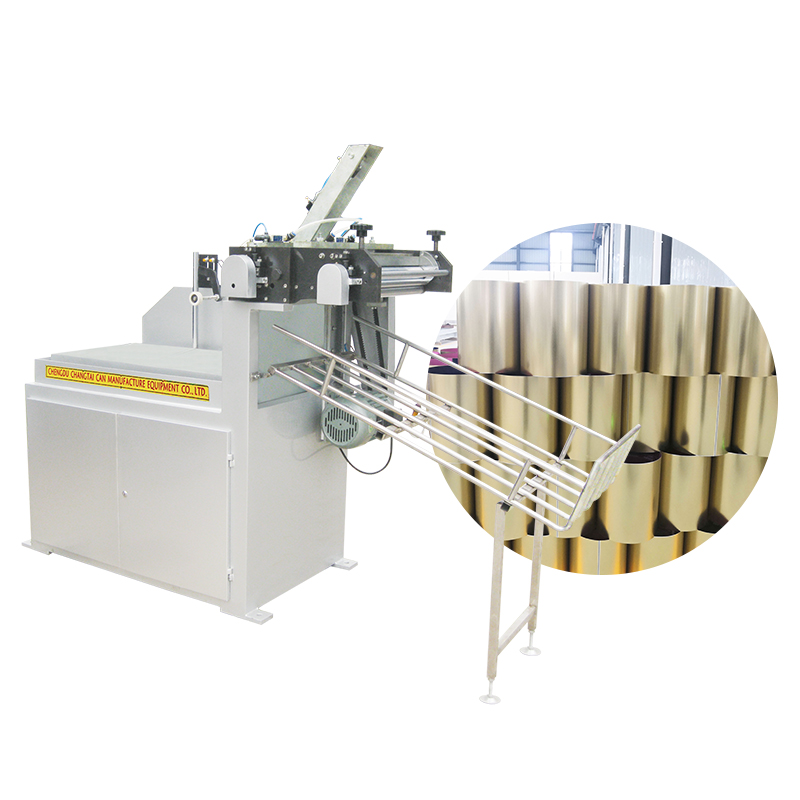

The stroke of the welder table is 300mm, and the back of the welder is equipped with a table, which can be loaded by a forklift, reducing the time for adding iron. The rounding adopts the upper suction type, which has low requirements on the cutting size of the iron sheet, and there is no need to adjust the rounding machine material rack to change the can type. The can delivery tank is made of stainless steel integral tank. Change tank type quickly.

Each diameter is equipped with a corresponding tank delivery channel. It only needs to remove two screws, remove the can channel of the can feeding table, and then put another can channel in, so that it only takes 5 minutes to change a can type. The machine is equipped with LED lights on the front and above the roll, which is convenient for observing the running status of the machine.