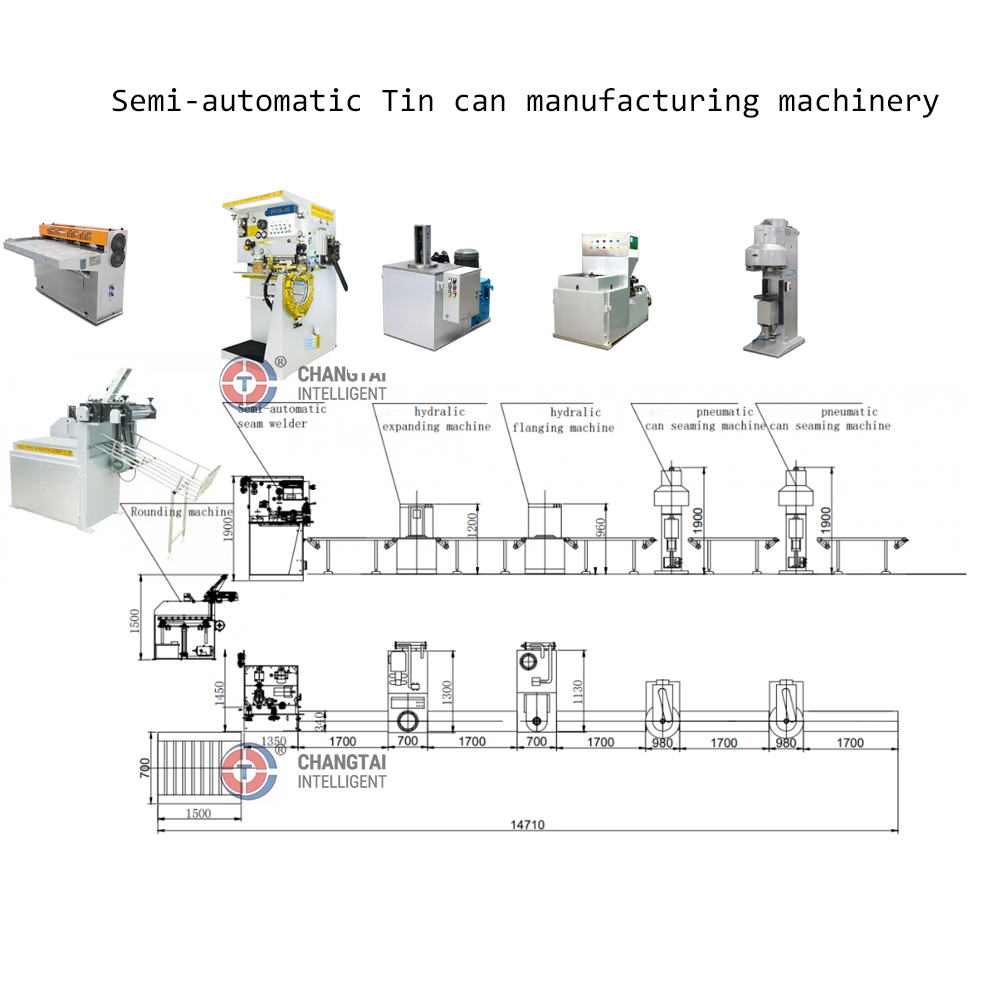

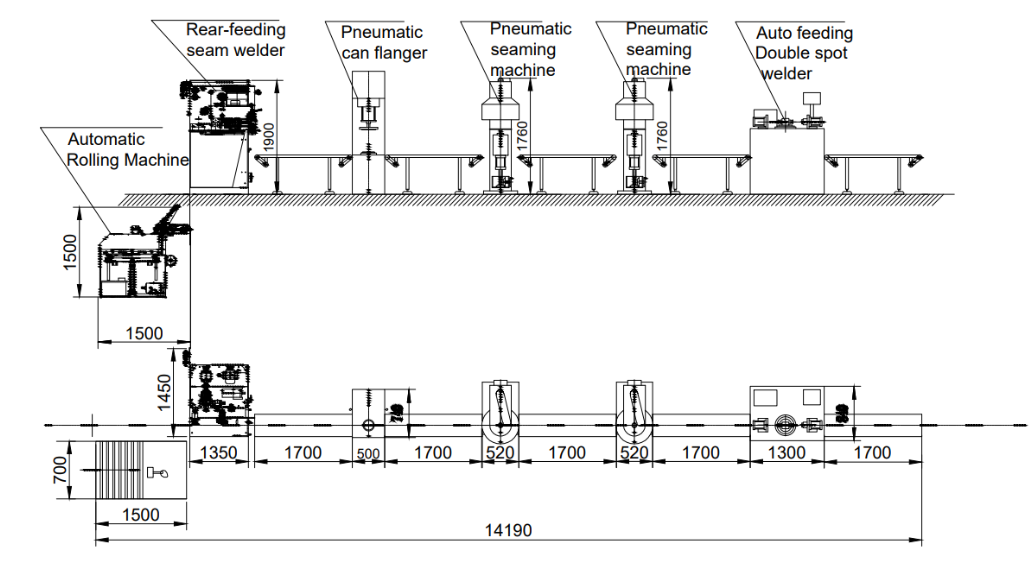

30-50L semi-automatic large barrel can production line

30-50L semi-automatic large barrel can production line

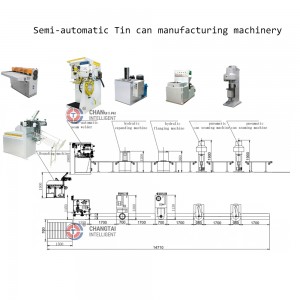

Semi-automatic round can production line

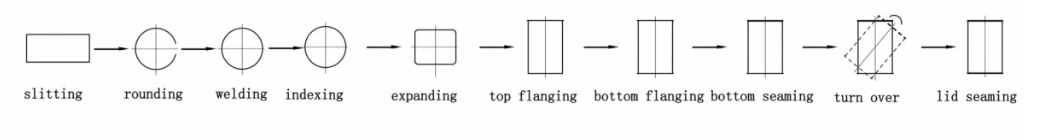

The can making production line is suitable for the semi-automatic production of 10-25L conical pail, which is composed of three metal plates: can body, can cover and can bottom. The can is conical. Technical flow:cutting the tin sheet to blank-rounding-welding-manual coating-conical expanding-flanging&pre-curling-curling&beading-bottom seaming-ear lug welding-manual handle assembly-packaging

Company Profile

Chengdu Changtai Intelligent Equipment Co., Ltd.was founded in 2007, a professional company which specialize in designing and manufacturing tin can making equipment,the products are widely used in petroleum,chemical,paint,coating,ventilation duct and etc. we has established long-term cooperative relations with many domestic companies, and has been exported to Southeast Asia, the Middle East, Africa, the United Kingdom and other countries and regions.Our products are well received by customers at home and abroad.

| Production capability | 10-80Cans/min 5-45Cans/min | Applicable can height | 70-330mm 100-450mm |

| Applicable can diameter | Φ70-Φ180mmΦ99-Φ300mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.15-0.42mm | Compressed air consumption | 200L/min |

| Compressed air pressure | 0.5Mpa-0.7Mpa | Power | 380V 50Hz 2.2KW |

| Machine dimension | 2100*720*1520mm | ||

| Welding speed | 6-18m/min | Production capability | 20-40Cans/min |

| Applicable can height | 200-420mm | Applicable can diameter | Φ220-Φ290mm |

| Applicable material thickness | 0.22~0.42mm | Applicable material | Tinplate,steel-based |

| Semi point distance | 0.5-0.8mm | Applicable copper wire diameter |

Φ1.38mm ,Φ1.5mm |

| Cooling water |

Temperature:20℃ Pressure:0.4-0.5Mpa Discharge:7L/min |

||

| Total power | 18KVA | Dimension |

1200*1100*1800mm |

| Weight | 1200Kg | Powder | 380V±5% 50Hz |