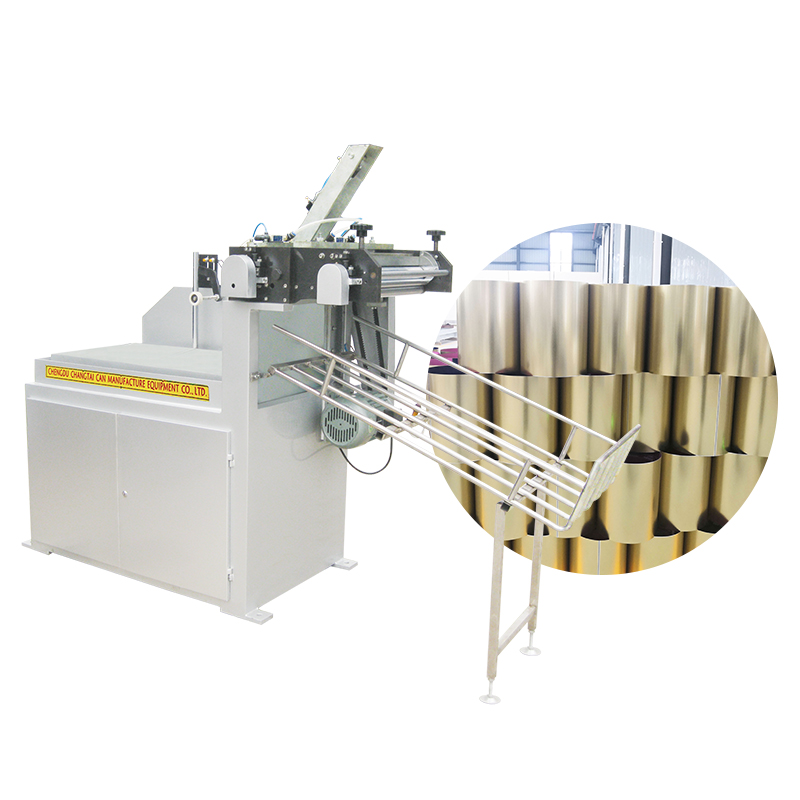

10L-25L tin can making machine metal food cans semi-automatic can welding machine

10L-25L tin can making machine metal food cans semi-automatic can welding machine

Technical Parameters

| Model | FH18-65 |

| Welding Speed | 6-18m/min |

| Production Capacity | 20-80cans/min |

| Can diameter Range | 65-286mm |

| Can Height Range | 70-420mm |

| Material | Tinplate/steel-based/chrome plate |

| Tinplate Thickness Range | 0.18-0.42mm |

| Z-bar Oerlap Range | 0.6mm 0.8mm 1.2mm |

| Nugget Distance | 0.5-0.8mm |

| Seam Point Distance | 1.38mm 1.5mm |

| Cooling Water | Temperature 12-18℃ Pressure:0.4-0.5MpaDischarge:7L/min |

| Power Supply | 380V±5% 50Hz |

| Total Power | 18KVA |

| Machine Measurements | 1200*1100*1800 |

| Weight | 1200kg |

Advantages:

One of the key advantages of a semi-automatic can welding machine is its ability to increase production efficiency while maintaining high-quality welds. Operators can quickly set up the machine for different can sizes, which reduces downtime during production changes. The semi-automatic nature allows for human oversight, ensuring that quality control is upheld without the need for fully manual operation. Additionally, these machines are typically more cost-effective than fully automatic models, making them accessible for small to medium-sized manufacturers. They also offer greater adaptability to various welding techniques, such as spot welding and seam welding, catering to diverse production needs.

Application Industries:

Semi-automatic can welding machines find application across various industries. The most prominent is the food and beverage industry, where they are used to manufacture aluminum and tin cans for products like soda, beer, and canned goods. Other applications include the cosmetics and personal care industries, where metal packaging is crucial for product preservation and aesthetics. Overall, the versatility of semi-automatic can welding machines makes them essential in any industry that requires reliable and efficient can production.