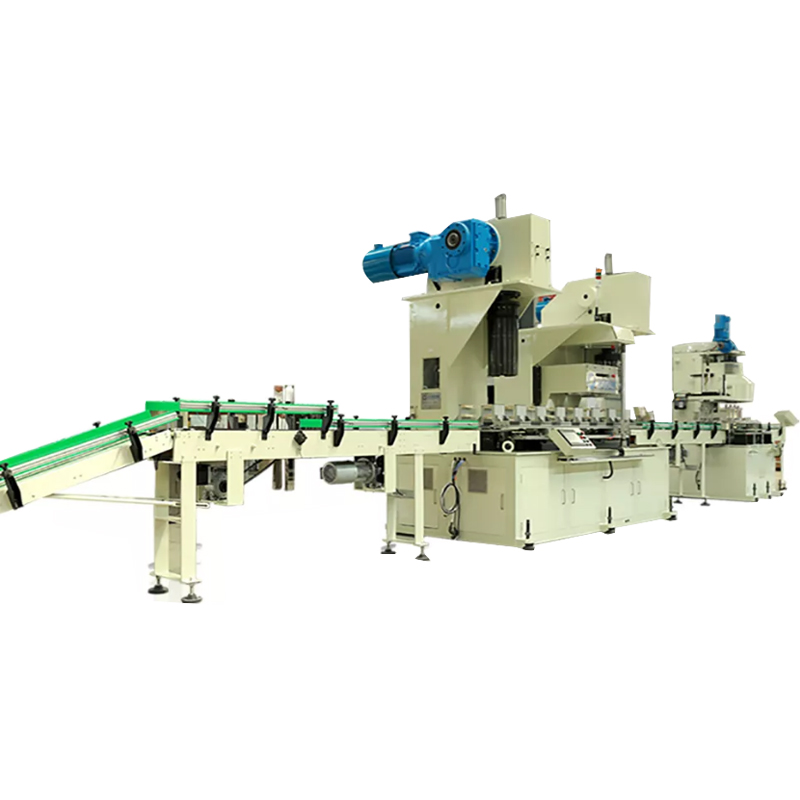

Automatic10-25L conical round can production line

Automatic10-25L conical round can production line

Automatic round can production line

This can making production line is designed for the automatic production of 10-25L conical pail,

which is composed of three metal plates: can body, can cover and can bottom.The can is conical.

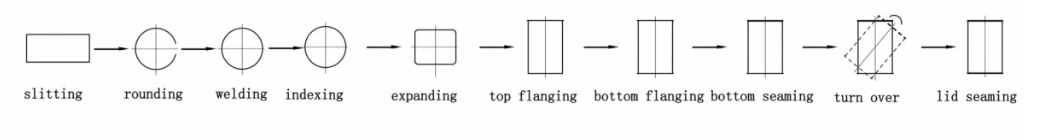

Technical flow:

1. Cutting the tin sheet to blank

2. Rounding & Welding

3. Inner and outer coating (inner powder coating and outer coating)

4. Drying & Cooling conveying

5. Conical & Expanding Flanging

6. Flanging、Curling 、Beading

7. Bottom lid feeding

8. Seaming

9. Turning over

10. Ear lug welding&coating&meal handle assembly

11. Leak testing-packaging

The advantages of conical pail making machine:

1. Heavy duty cast iron frame enclosed with stainless steel sheathing secured to the tubular frame making the machine durable, stable and reliable.

2. Mechanical transmission system makes it can work for life time with less maintenance.

3. Integrating pre-curling, notching, edging folding.

4. Compact design minimizes and saves valued space.

5. Operation is fully automatic with high efficiency and capacity.

6. This machine can make different sizes of tin plate cans by changing tooling.

7. PLC control and friendly touch screen HMI interface for easy adjustment.

8. Fault diagnosis system protects machine from damage.

9. Automatic lubricant system *Automatic alarm

10. This machine can work standalone or can be incorporated into your existing line.

China Metal Bucket Making Machine is used to make 10-25L round metal pail, barrels, drums, buckets, such as paint, oil, glue pails. If you want to make different size of such barrels, it just need to change moulds of the machines. The bucket size can be customized according to your needs.

Operating process

▶First place the cut can body materials into the automatic resistance welding machine's feeding table,Suck by the vacuum suckers,send the tin blanks to the feeding roller one by one.through the feeding roller,the single tin blank is fed to the rounding roller to conduct rounding process.

▶Then it will be fed to the rounding forming mechanism to make rounding.The body is fed into the resistance welding machine and make welding after the accurate positioning.

▶After welding,the can body is automatically fed into the rotary magnetic conveyor of the coating machine for outer coating,inner coating or inner powder coating, Which depends on customer's various need.It is mainly used to prevent the side welding seam line from being exposed in air and rusting.

▶The can body should be placed in induction drying oven to dry if it's inner coating or inner powder coating.Afer drying,It will be fed to cooling device to make natural cooling.

▶The cooled can body is then fed to the conical pail combination machine,and the can body is in an upright state going through the uprighting conveyor.

▶The first operation is the can body conical expansion.When the can body is in position,on the can body lifting tray which is controlled by a servo motor,and the can body is sent by this lifting tray to the conical expanding mold to make conical expanding.

▶The step 2 is pre-flanging The step 3 is curling.The upper mold is fixed on the machine body,and the lower mold,which is mounted on the CAM,completes the flanging and curling when the CAM is jacked up.The step 4 is beading.

▶After completing the above four steps,When the bottom lid auto feeder detects the can body coming,It will automatically feed one bottom lid to the top of the can body,and then both the can body and the bottom lid will be clamped to seaming machine head to make auto seaming.

▶After bottom seaming, it is fed to automatic double spots ear lug welding machine,through automatic side welding seam indexing,Cam conveyor conveying,mechanic paint breaking,also equipped with automatic ear lugs vibrating discs,finish accurate welding task on conical pail.

▶Then,The pail is fed to handle making and assembly station to finish automatic handle assembly.

▶Lastly,The finished can is conveyed to the automatic leak testing station by conveyor.

Through the accurate air source detecting step,The unqualified products will be tested and fed to the fix area.The qualified pails will come to the packing table for the final packaging.

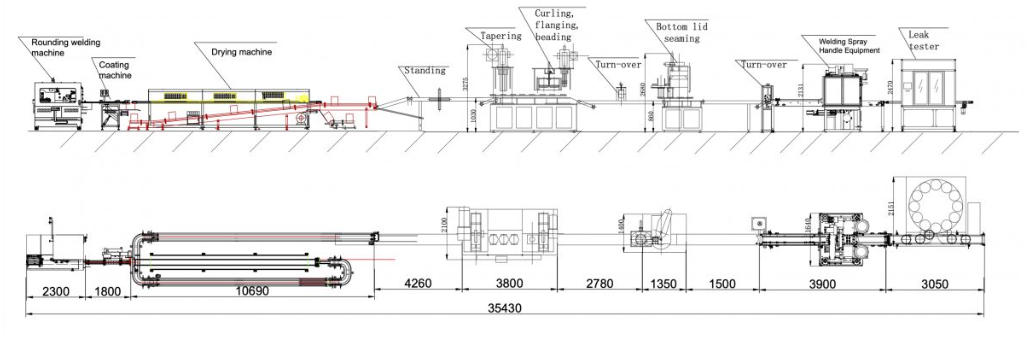

Equipment composition of round cans automatic production line

| First cut(min width) | 150mm | Second cut(min width) | 60mm |

| Speed (pcs/min) | 32 | Thickness of sheet | 0.12-0.5mm |

| Power | 22kw | Voltage | 220v/380v/440v |

| Weight | 21000kg | Dimension(L*W*H) | 2520X1840X3980mm |

| Model | CTPC-2 | Voltage&Frequency | 380V 3L+1N+PE |

| Production speed | 5-60m/min | Powder consumption | 8-10mm&10-20mm |

| Air consumption | 0.6Mpa | Can body range | D50-200mm D80-400mm |

| Air requirement | 100-200L/min | Power consumption | 2.8KW |

| Machine dimension | 1080*720*1820mm | Gross weight | 300kg |

| Frequency range | 100-280HZ | Welding speed | 8-15m/min |

| Production capability | 25-35Cans/min | Applicable can diameter | Φ220-Φ300mm |

| Applicable can height | 220-500mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.2~0.4mm | Applicable copper wire diameter |

Φ1.8mm ,Φ1.5mm |

| Cooling water |

Temperature: 12-20℃ Pressure:>0.4Mpa Flow:40L/min |

||

| Total power | 125KVA | Dimension |

2200*1520*1980mm |

| Weight | 2500Kg | Powder | 380V±5% 50Hz |

| Can height range | 50-600mm | Can diameter range | 52-400mm |

| Roller speed | 5-30m/min | Coating type | Roller coating |

| Lacquer width | 8-15mm 10-20mm | Main supply&Current load | 220V 0.5 KW |

| Air consumption | 0.6Mpa 20L/min | Machine dimension& Net weight | 2100*720*1520MM300kg |

| Burner power | 1-2KW | Burner heating speed | 4m-7m/min |

| Suitable small can diameter | Φ45-Φ176mm | Suitable big can diameter | Φ176-Φ350mm |

| Can height | 45mm-600mm | Cooling water | >0.4Mpa,12-20℃,40L/min |

| Air consumption | ≥50L/min>0.5Mpa | ||

Automatic can body combination System

| Production capacity | 25-30cpm | Range of can Dia | 200-300mm |

| Range of can height | 170-460mm | thickness | ≤0.4mm |

| Total power | 44.41KW | Pneumatic system pressure | 0.3-0.5Mpa |

| Body uprighting conveyor size | 4260*340*1000mm | Combination machine size | 3800*1770*3200mm |

| Electric carbinet size | 700*450*1700mm | Weight | 9T |