Automatic10-20L square can production line

Automatic10-20L square can production line

Main Features

1. More than 20 years experience and reputation both at home and abroad;

2. Quality Assurance, excellent after service and reasonable price;

3. Reliable and safe to control, easy to operate and maintain;

4. Equipped with human-computer interface and PLC; adopt digital control technology;

5. Full automatic, semi-automatic, and multi mould, suitable for different cans shape and size.

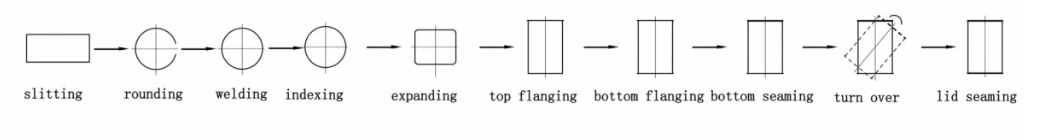

Big square can automatic production line operating process

First, place the cut can body materials into the automatic resistance welding machine's feeding table,Suck by the vacuum suckers,send the tin blanks to the feeding roller one by one.through the feeding roller,the single tin blank is fed to the rounding roller to conduct rounding process,then it will be fed to the rounding forming mechanism to make rounding.

The body is fed into the resistance welding machine and make welding after the accurate positioning.After welding,the can body is automatically fed into the rotary magnetic conveyor of the coating machine for outer coating,inner coating or inner powder coating, Which depends on customer's various need.It is mainly used to prevent the side welding seam line from being exposed in air and rusting.The can body should be placed in induction drying oven to dry if it's inner coating or inner powder coating.Afer drying, It will be fed to cooling device to make natural cooling.

The cooled can body is then fed to the big square can combination machine,and the can body is in an upright state going through the uprighting conveyor.It is fed to the first automatic side welding seam indexing station by the clamps.The second station is square expanding.When the can body is in position,on the can body lifting tray which is controlled by a servo motor,and the can body is sent by this lifting tray to the square expanding mold to make square expanding.The third station is to make panel and corner embossing.

When the can body is in position, on the can body lifting tray which is controlled by a servo motor,and the can body is sent by this lifting tray to the make panle and corner embossing at a time.The fourth station is top flanging,the fifth station is bottom flanging.The bottom flanging:the can will be sent to the bottom flanging mold lying on the upper part of the machine by lifting tray to make it.The top flanging:the upper cylinder will press the can body to the position of top flanging mold to make it.

Both the top and bottom can body flanging are each driven by four cylinders.The sixth station is automatic lid detecting and feeding and seaming.After the above six procedures,the can will be reversed up and down by reversing device,and then make top seaming,this process is the same as the bottom seaming process.Lastly.the finished can is fed by conveyor to automatic leak tester station.After accurate air source inspection,unqualified products are detected and pushed to a fixed area,and qualified products will come to the packaging workbench for the final packaging process.

Constituent parts of this metal can making line

| First cut/min width | 150mm | Second cut/min width | 60mm |

| Speed /pcs/min | 32 | Thickness of the sheet | 0.12-0.5mm |

| Power | 22KW | Voltage | 220v 380v 440v |

| Weight | 21100kg | Machine Dimension | 2530X1850X3990mm |

In a typical canbody production line, the slitter is the first stage in the manufacturing process. It cuts printed and lacquered metal sheets into body blanks of the required size. The addition of a blank stack transfer unit further increases the slitter’s efficiency.

Our slitters are custom-made. They are extremely robust, facilitate simple, swift adjustment to different blank formats and ensure exceptionally high precision.When it comes to versatility, precision, reliability and production speed, our slitters are so suitable for tin canbody producing.

| Model of the machine | CTPC-2 | Voltage&Frequency | 380V 3L+1N+PE |

| Speed | 5-60m/min | Powder consumption | 8-10mm&10-20mm |

| Air consumption | 0.6Mpa | Can diameter range | D50-200mm D80-400mm |

| Air requirement | 100-200L/min | Power consumption | 2.8KW |

| Dimensions | 1090*730*1830mm | Weight | 310kg |

Powder coating system is one of the powder coating products launched by Changtai Company. This machine is dedicated to the spray coating technology of tank welds of can manufacturers. Our company adopts advanced powder coating technology, which makes the machine novel structure, high system reliability, easy operation, wide applicability and high performance-price ratio. And the use of reliable control components, and touch control terminal and other components, making the system more stable and reliable.

| Frequency range | 100-280HZ | Welding speed | 8-15m/min |

| Production capability | 25-35Cans/min | Applicable can diameter | Φ220-Φ300mm |

| Applicable can height | 220-500mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.2~0.4mm | Applicable copper wire diameter |

Φ1.8mm ,Φ1.5mm |

| Cooling water |

Temperature: 12-20℃ Pressure:>0.4Mpa Flow:40L/min |

||

| Total power | 125KVA | Dimension |

2200*1520*1980mm |

| Weight | 2500Kg | Powder | 380V±5% 50Hz |

The canbody welder is at the heart of any three-piece can production line. It forms the body blanks into their basic shape and welds the seam overlap. Our Superwima welding principle requires only a minimal overlap of a few tenths of a millimeter. Optimum control of the welding current combined with precision-matched pressure on the overlap. Since the launch of the new generation of welders, customers all over the world have confirmed today their considerable satisfaction on an outstanding and a high machine reliability combined with an economical and an efficient production. New industrial standards have been set in the manufacture of canbodies worldwide.

| Applicable Can height | 50-600mm | Applicable Can diameter | 52-400mm |

| Roller speed | 5-30m/min | Coating type | Roller coating |

| Lacquer width | 8-15mm 10-20mm | Main supply and Current load | 220V 0.5 KW |

| Air consumption | 0.6Mpa 20L/min | Machine dimension& | 2100*720*1520MM300kg |

Powder coating machine is an important part of the three-piece can production line, which is highly praised by customers at home and abroad in the market and is an excellent can making equipment. Chengdu Changtai is committed to providing customers with the best quality can making equipment and developing the best solution.

| Conveyor speed | 5-30m/min | Can diameter range | 52-180mm |

| Conveyor type | Flat chain drive | Cooling diduct. coil | Not require water/air |

| Effictive heating | 800mm*6(30cpm) | Main supply | 380V+N>10KVA |

| Heating type | Induction | Sensing distance | 5-20MM |

| Higher Heating | 1KW*6(temperature set) | Induction point | 40MM |

| Frequency setting | 80KHz+-10 KHz | Induction time | 25Sec(410mmH,40CPM) |

| Electro.Radiation protective | Covered with safety guards | Rise time(MAX) | Distance 5mm 6sec&280℃ |

| Demension | 6300*700*1420mm | Net Weight | 850KG |

Changtai has a modular range of curing systems designed to harden the seam protection layer effectively. Immediately after the application of the lacquer or powder seam protection layer, the canbody goes heat treatment. We have developed advanced gas or induction-operated modular heating systems with automatic temperature regulation and speed-adjustable conveyor belts. Both heating systems are available in linear or U-shape layout.

Automatic can body combination machine

| Production capacity | 30-35cpm | Range of can Dia | 110-190mm |

| Range of can height | 110-350mm | Thickness | ≤0.4 |

| Total power | 26.14kw | Pneumatic system pressure: | 0.3-0.5Mpa |

| Body uprighting conveyor size | 2350*240*930mm | Infeed conveyor size | 1580*260*920mm |

| Combination machine size | 2110*1510*2350mm | Weight | 4T |

| Electric carbinet size |

710*460*1800mm |

||

A can production line usually ends with a palletizer. The pail assembly line ca be customized, which will ensure stacks that can be palletized in a next steps.

Automatic round can production line

The can making production line is suitable for the automatic production of 10-20L square can, which is composed of three metal plates: can body, can cover and can bottom. The can is square shaped.

Technical flow:cutting the tin sheet to blank-rounding-welding-inner and outer coating

(inner powder coating and outer coating)-drying-cooling conveying-square expanding-panel,

corner embossing-upper flanging-lower flanging-bottom lid feeding-seaming-turning over-

top lid feeding-seaming-leak testing-packaging