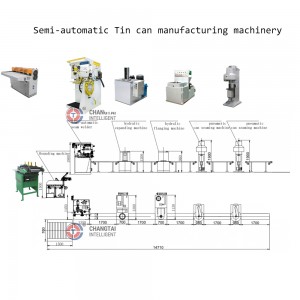

0.1-5L semi-automatic round can production line

0.1-5L semi-automatic round can production line

Semi-automatic round can production line

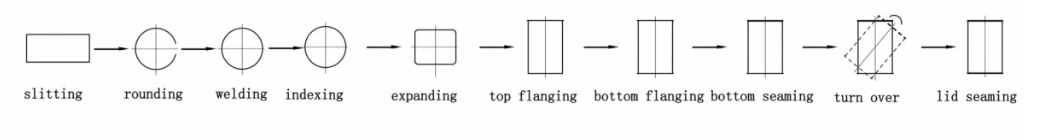

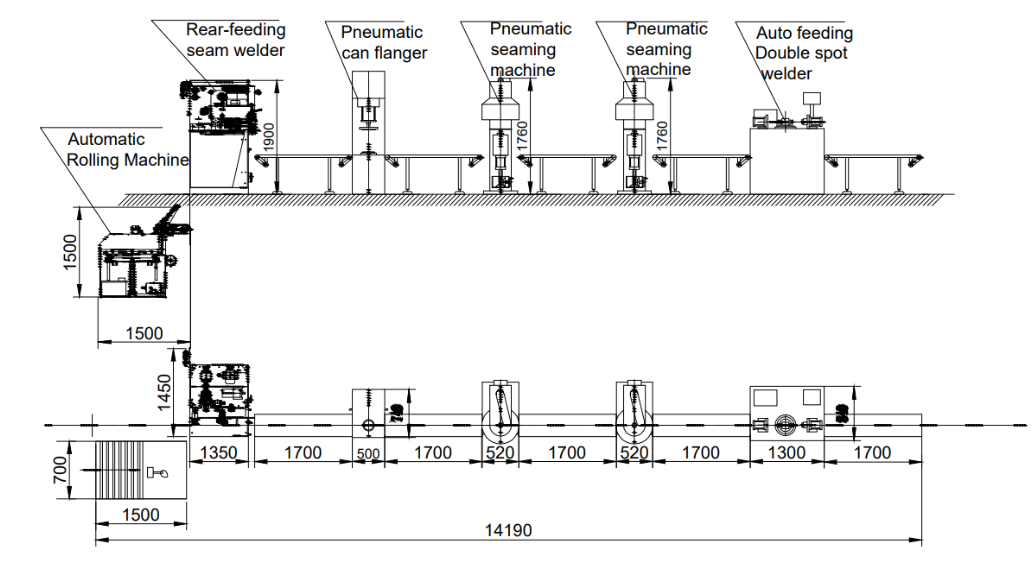

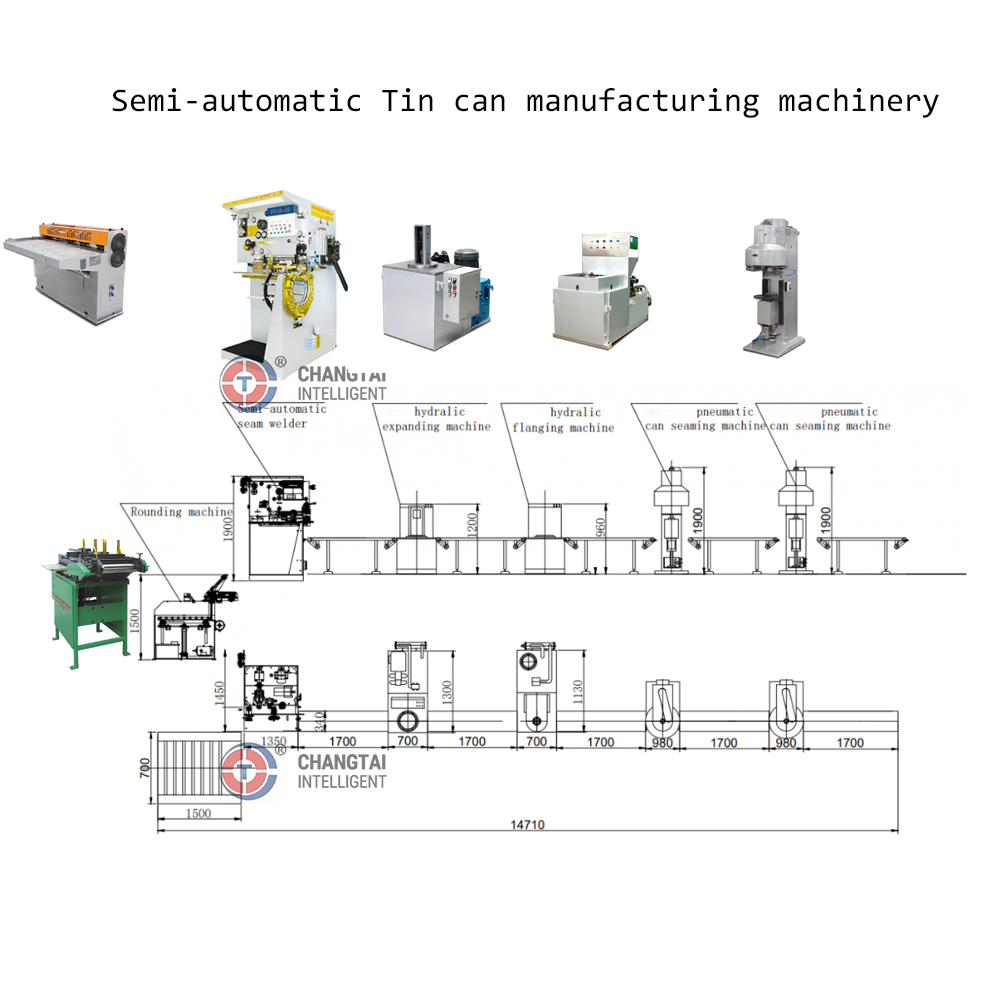

The can making production line is suitable for the semi-automatic production of 0.1-5L round can, which is composed of three metal plates: can body, can cover and can bottom. The can body is round.Technical flow:cutting the tin sheet to blank-rounding-welding-manual coating-flanging-bottom seaming-top seaming-ear lug welding-packaging

Features

1.Panasonic PLC and Mitsubishi frequency conversion speed governor control system,

2.Welding frequency is adjustable with constant current and attenuation function at front & back end

3.Sensor can precise control the welding current location at front & back end,change copper wire speed.

4.Change the gauge tooling can welding different size of cans.

5.Comprehensive monitoring the equipment running,with failure self-detected alarms and provide solution system.

6.Apply to the welding of various flashlight,small aerosal cans.

7.Can body internal and external pre-painting machine and can body drier are optional to be added in production line.

8.According to customer’s demands to accelerate speed.

| Production capability | 30-120Cans/min | Applicable can height | 70-320mm 70-280mm |

| Applicable can diameter | Φ50-Φ180mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.15-0.35mm | Compressed air consumption | 600L/min |

| Compressed air pressure | 0.5Mpa-0.7Mpa | Power | 380V 50Hz 1KW |

| Machine dimension | 700*1100*1200mm 650*1100*1200mm | ||

| Welding speed | 6-18m/min | Production capability | 20-80Cans/min |

| Applicable can height | 70-320mm&70-420mm | Applicable can diameter | Φ52-Φ180mm&Φ65-Φ290mm |

| Applicable material thickness | 0.18~0.42mm | Applicable material | Tinplate,steel-based |

| Semi point distance | 0.5-0.8mm | Applicable copper wire diameter |

Φ1.38mm ,Φ1.5mm |

| Cooling water |

Temperature:12-18℃ Pressure:0.4-0.5Mpa Discharge:7L/min |

||

| Total power | 18KVA | Dimension |

1200*1100*1800mm |

| Weight | 1200Kg | Powder | 380V±5% 50Hz |