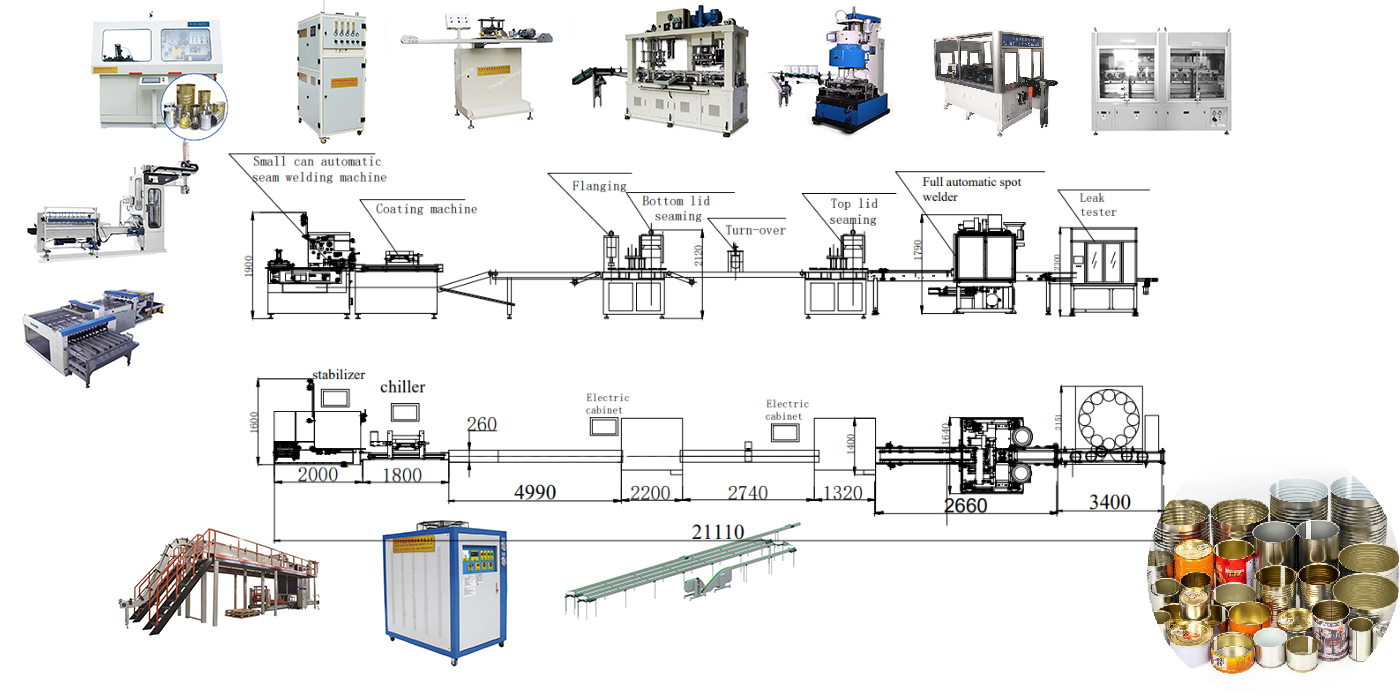

Automatic 0.1-5L round can production line

Automatic 0.1-5L round can production line

Automatic round can production video

The can making production line is suitable for the automatic production of 0.1-5L round can, which is composed of three metal plates: can body, can cover and can bottom. The can body is round.

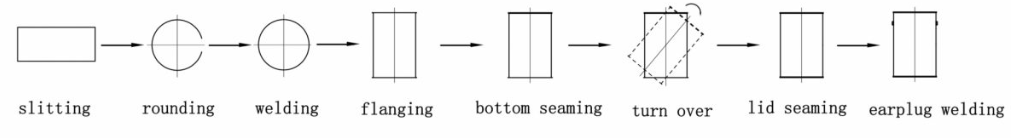

Technical flow:cutting the tin sheet to blank-rounding-welding-outer coating-flanging-bottom lid feeding-seaming-turning over-top lid feeding-seaming-+ear lug welding-leak testing-packaging

Working process of automatic round tin can production line

In the working process of the automatic round can production line.

The cut can materials are first put into the feeding table of the automatic resistance welder, sucked out by the vacuum sucker, and the tin blanks are sent to the feeding roller one by one.

Through the feeding roller, the single tin blank is sent to the fillet roller for fillet processing, and then sent to the fillet forming mechanism for rounding.The body is sent to the resistance welder and welded after precise positioning.

After the welding is completed, the can is automatically sent to the rotating magnetic conveyor of the coater for external coating, internal coating or internal powder coating, which can be carried out according to the various needs of customers.Mainly used to prevent the side weld line from being exposed to air rust. The can is fed into the combination machine, the can is in an upright state, through the upright conveyor.And by the fixture to the flanging station. The flanging task is accomplished by the collision of the upper and lower flanging molds.

After that, the can with flange is sent to the automatic lower cover feeder, and the incoming can is detected by the detection sensor. The lower cover feeder will automatically send the lower cover to the top of the can, and send the can and the bottom of the can to the position below the sealing block. The lifting plate will send the can and the bottom of the can to the sealing machine head to seal.With one end stitched.It is sent to the can body turning machine to turn over the can body, and then to carry out automatic cap detection and welding.

Then, it is sent to the automatic double-point ear-ear welder, which completes the precise welding task of the small round can through automatic side weld indexing, CAM conveyor conveying, mechanical paint breaking, and equipped with automatic ear-ear vibration plate.

Finally, the finished product can is sent to the automatic leak detection station by the conveyor.

After accurate air source detection, unqualified products are detected and pushed to the fixed area. Qualified products will come to the packaging workbench for final packaging.

Equipment composition of round cans automatic production line

Duplex slitter

| First cut(min width) | 150mm | Second cut(min width) | 60mm |

| Speed (pcs/min) | 32 | Thickness of sheet | 0.12-0.5mm |

| Power | 22kw | Voltage | 220v/380v/440v |

| Weight | 21000kg | Dimension(L*W*H) | 2520X1840X3980mm |

In a typical can body production line, the slitter is the first stage in the manufacturing process. It cuts printed and lacquered metal sheets into body blanks of the required size. The addition of a blank stack transfer unit further increases the slitter’s efficiency. Our slitters are custom-made. They are extremely robust, facilitate simple, swift adjustment to different blank formats and ensure exceptionally high precision.When it comes to versatility, precision, reliability and production speed, our slitters are so suitable for tin canbody producing.

The duplex slitter or tinplate sheet slitter is one of the most important pieces of equipment in a 3-piece can production line.it is the first station of the can making line. It is used to cut the tinplate sheet or stainless steel sheet as can body blanks of required size or strips for can ends. High quality duplex slitter is the fisrt progress in an optimal solution for metal packaging factory.Versatile, Precise and Robust are the basic requirements for a duplex slitter.

The slitter consists of feeder, shear, electrical control box, vacuum pump, loader and sharpener. The multifunctional slitter is versatility which it can feed automatically, vertical, horizontal cutting automatically, duplex detection and electromagnetism counting.

| Frequency range | 120-320HZ | Welding speed | 6-36m/min |

| Production capability | 30-200Cans/min | Applicable can diameter | Φ52-Φ99mm&Φ65-Φ180mm |

| Applicable can height | 55-320mm | Applicable material | Tinplate,steel-based,Chrome plate |

| Applicable material thickness | 0.16~0.35mm | Applicable copper wire diameter | Φ1.38mm ,Φ1.5mm |

| Cooling water |

Temperature: ≤20℃ Pressure:0.4-0.5Mpa Flow:10L/min |

||

| Total power | 40KVA | Dimension | 1750*1500*1800mm |

| Weight | 1800Kg | Powder | 380V±5% 50Hz |

The automatic can body welding machine is at the heart of any three-piece can production line. It forms the body blanks into their basic shape and welds the seam overlap. Our Superwima welding principle requires only a minimal overlap of a few tenths of a millimeter. Optimum control of the welding current combined with precision-matched pressure on the overlap. Since the launch of the new generation of welders, customers all over the world have confirmed today their considerable satisfaction on an outstanding and a high machine reliability combined with an economical and an efficient production. New industrial standards have been set in the manufacture of can bodies worldwide.

| Model | CTPC-2 | Voltage&Frequency | 380V 3L+1N+PE |

| Production speed | 5-60m/min | Powder consumption | 8-10mm&10-20mm |

| Air consumption | 0.6Mpa | Can body range | D50-200mm D80-400mm |

| Air requirement | 100-200L/min | Power consumption | 2.8KW |

| Machine dimension | 1080*720*1820mm | Gross weight | 300kg |

Powder coating system is one of the powder coating products launched by Chengdu Changtai Company. This machine is dedicated to the spray coating technology of can welds of can manufacturers. Our company adopts advanced powder coating technology, which makes the machine novel structure, high system reliability, easy operation, wide applicability and high performance-price ratio. And the use of reliable control components, and touch control terminal and other components, making the system more stable and reliable. The powder coating machine uses static electricity to spray plastic powder on the weld of the can body, and the solid powder is melted and dried by heating in the oven to form a layer of plastic protective film (polyester or epoxy resin) on the weld. Because the powder can completely and evenly cover the burrs and high and low surfaces on the weld according to the specific shape of the weld by the principle of electrostatic adsorption during spraying, it can well protect the weld from the corrosion of the contents; At the same time, because the plastic powder has high corrosion resistance to various chemical solvents and sulfur, acid and high protein in food, the powder spraying is suitable for a variety of different contents; And because the excess powder after powder spraying adopts the principle of recycling and reuse, the powder utilization rate is high, and it is the most ideal choice for weld protection at present.

| Can height range | 50-600mm | Can diameter range | 52-400mm |

| Roller speed | 5-30m/min | Coating type | Roller coating |

| Lacquer width | 8-15mm 10-20mm | Main supply&Current load | 220V 0.5 KW |

| Air consumption | 0.6Mpa 20L/min | Machine dimension& Net weight | 2100*720*1520MM300kg |

Effective protection of the weld seam is crucial to the quality of a three-piece can. That’s why we offer a broad range of seam protection technologies and systems. After welding, the next step in the manufacture of a quality can is the application of a durable protective layer to the inner and outer seams. We supply fully automatic powder-coating or wet-lacquering systems for inner and outer seams. Our seam protection systems can be customized to all system configurations, production speeds and can body sizes. They guarantee easy, clean operation and low powder or lacquer consumption.

| Conveyor speed | 5-30m/min | Can diameter range | 52-180mm |

| Conveyor type | Flat chain drive | Cooling diduct. coil | Not require water/air |

| Effictive heating | 800mm*6(30cpm) | Main supply&Current load | 380V+N>10KVA |

| Heating type | Induction | Sensing distance | 5-20MM |

| Higher Heating | 1KW*6(temperature set) | Induction point | 40MM |

| Frequency setting | 80KHz+-10 KHz | Induction time | 25Sec(410mmH,40CPM) |

| Electro.Radiation protective | Covered with safety guards | Rise time(MAX) | Distance 5mm 6sec&280℃ |

| Demension |

6300*700*1420mm |

Weight | 850KG |

Automatic can body combination machine

| Production capacity | 60cpm | Range of can Dia | 52-180mm |

| Range of can height | 80-320mm | thickness | ≤0.35 |

| Total power | 13.1kw | Pneumatic system pressure: | 0.5Mpa |

| Body uprighting conveyor size | 2250*230*920mm | The front section conveyor size | 2740*260*880mm |

| Seaming machine size | 2200*1120*2120mm | Weight | 5.5T |

Our multi-function systems perform multiple operations in one automatic can body combination machine at low, medium and high speeds. Forming and assembling of can body in linear or carrousel body shapers for all production speeds, and special applications. All systems feature high-level modularity and process capability and are suitable for a wide range of applications, including parting, shaping, necking, flanging, beading and seaming. With fast, simple retooling, they combine extremely high productivity with top product quality, while offering high safety levels and effective protection for operators.

If you have got some parts of can making machines, or if you just need some parts of our can making equipment, we are happy to hear from you!

Welcome to choose the right machines for your can making line!